FlexRake® FRO

Rake Only Option

FlexRake device mounts onto existing bar rack

Automated raking solution for existing trash racks and bar screens

Cost-effective solution with flexrake® adaptive technology™ for existing trash racks

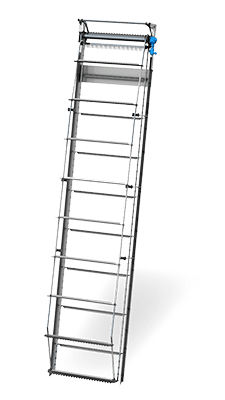

The FlexRake® Rake Only (FRO) is an automated raking mechanism designed to be mounted onto existing screens (on the deck or on the screen itself depending on the site). This retrofit option is an economical and effective way to utilize existing screens for bar openings ½ inch to 4 inches (or greater).

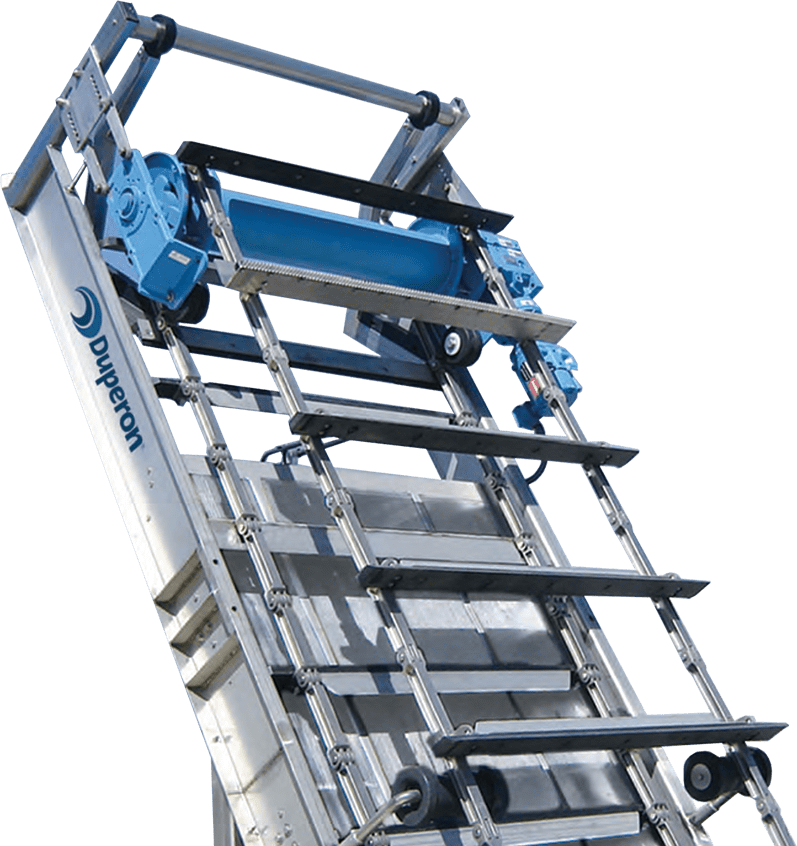

The FlexRake FRO is a heavy-duty raking mechanism engineered for open channel applications where debris size and velocity may be unpredictable. It can handle general refuse, aquatic vegetation, tree limbs, tree branches and shrubs to lumber, tires, oil drums, and automobile frames. Its reliability and unmatched adaptability translate into everyday pump protection and reliable performance in events of significant magnitude.

Duperon has more than 35 years of delivering solutions with simple, yet robust equipment that maximizes water flow and is resilient enough to weather any storm.

Applications:

- Open channels

- Water intakes

- Coarse screens

- Stormwater irrigation

- Canals

- Pump stations

- Flood control

- Hydroelectric

- Drainage canals

- Combined sewer overflows

- Wastewater applications

The Duperon®

Difference

The Duperon®

FlexRake® FRO

Cost-Effective Automation

Installs on existing manual bar racks or can replace existing technology for cost-effective and automated debris removal

Customizable

To fit your existing bar rack and the unique needs of your site

Flexible Design

Adapts to a range of unpredictable flow and debris conditions without operator intervention

No in-channel maintenance

With no lower sprocket, the FlexRake FRO allows maintenance to be performed from the deck, eliminating diving or confined space entry for improved worker safety

Reliable operation

Designed for 24/7 operation or can stand idle for long periods, yet reliably respond when needed during a storm or debris event

Low cost of ownership

Fractional horsepower, few parts, minimal maintenance; the FlexRake FRO is easy to install, own, and operate by your own crew

Uninterrupted water flow

Continuously cleans the entire intake with multiple scrapers to avoid blinding and headloss to ensure water keeps moving

Wildlife-friendly

The FlexRake® HD received Manatee Safe designation from the US Army Corps of Engineers (USACE), US Fish & Wildlife Services (FWS) and Florida Fish and Wildlife Conservation Commission (FWC)

Our solutions are simple

Our Solutions Are Simple

St. Charles Parish, Louisiana is situated 25 miles outside of New Orleans. Located in a floodplain, most of the Parish is at or below sea level. To mitigate the risk of flooding, the Parish uses a series of drainage canals and pumping stations that are imperative for flood control and to move stormwater. This levee system protects against the loss of life and property and is critical to maintain operation during rainfall and hurricane events.

Many of the pump stations had manual trash racks that protected the pumps from destructive debris. Overtime the debris conditions changed and it was determined automated screening was required.

To save costs, St. Charles Parish purchased FlexRake® Rake Only devices that were custom fit to their existing trash racks. In true form to Duperon’s design standard for simplicity, thirteen units were installed across three sites in only three days… using their own crew.

These FlexRakes have proven a dependable, cost-effective solution. It has withstood seasonal weed blooms, storms and protected the community from hurricane floodwaters. Its reliability and unmatched adaptability translate into everyday pump protection and reliable performance in events of significant magnitude.

Description

The FlexRake® FRO is a front-clean, front-return, mechanical raking system that mounts onto an existing bar rack. It features the industry leading FlexLink™ multifunctional link system, which eliminates underwater sprockets, bearings or tracks that create a fixed path of travel and are subject to fouling and/or jamming. The groundbreaking flex/pivot action of the Duperon FlexRake is unhampered by large debris.

The FlexRake FRO is designed to rake existing bar racks with openings of ½ inch to 4 inches wide. UHMW-PE scrapers are custom-fit to clean the existing bar rack.

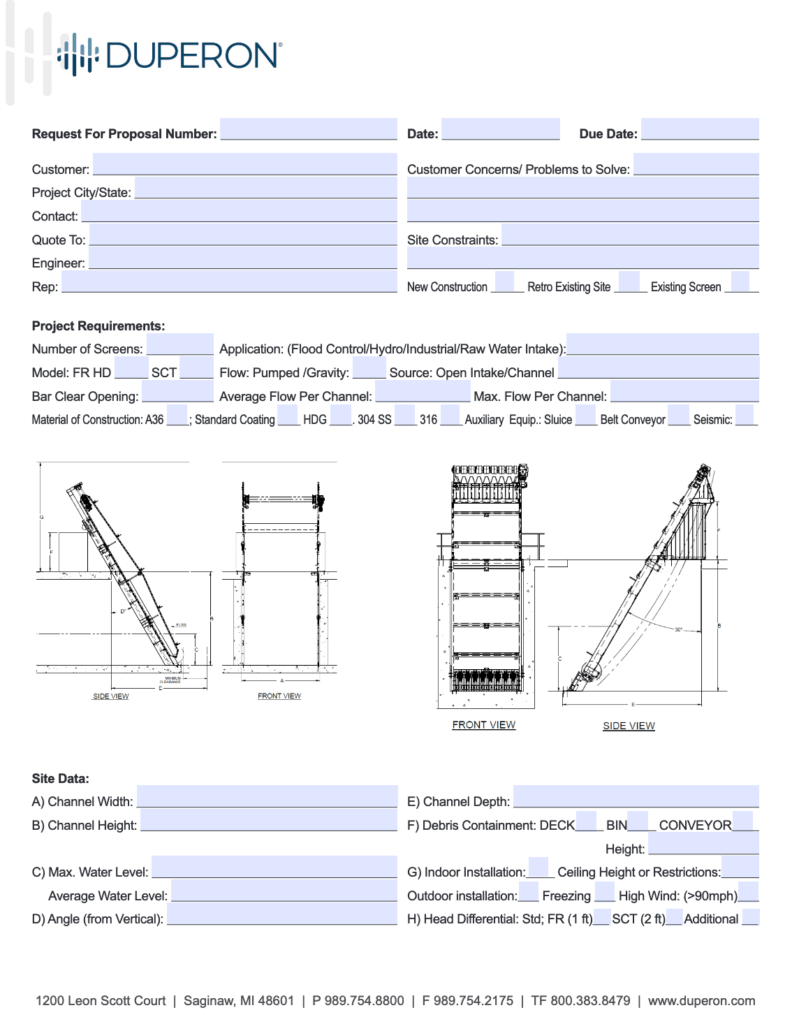

General Specs

| Typical Applications | Open channels, water intakes, coarse screens, irrigation canals, stormwater pump stations, flood control, hydroelectric, wastewater, combined sewer overflows and other applications |

| Unit Width | 2 ft to 10 ft |

| Unit Length | 10 ft to 100 ft |

| Bar Openings | Site dependent – uses existing trash rack or bar screen |

| Scrapers | UHMW-PE scrapers – configuration dependent on site and application |

| Cleaning Frequency | 2.3 ft/minute |

| Lifting Capacity | 1000 lbs

3000 lbs option available |

| Angle of Installation | Using existing bar rack |

| Mounting Options | Side fab or I-Beam available |

| Typical Motor | 1/4 HP 1 PH, 115/230 VAC OR 3 PH, 230/460 VAC, weatherproof motor |

| Standard Controls | Packages range from simple start/stop to sophisticated automation.

Motor overload protection provided. |

| Operation Options | Continuous/Manual

Automatic with timer, float, SCADA, differential/high-level sensing options with I/O as needed |

Key Features

A customized raking solution for your existing bar rack to preserve materials and costs

Industry-leading FlexLink™ eliminates lower sprockets, submerged bearings and tracks

FlexLink multifunctional link system has ultimate strength of 60,000 lbs with unmatched durability

Jam Evasion™ technology lifts and pivots around debris to remove from channel without shutdown or jamming

Swinging drivehead allows the entire raking system to move outward to discharge large debris

Full-Screen Cleaning™ reduces the risk of blinding at the intake by cleaning all of the screen all of the time

Fractional horsepower motors used for energy efficiency

Everything is serviceable from the deck to eliminate in-channel maintenance and confined space entries

Schematic

Photo Gallery

Case Studies

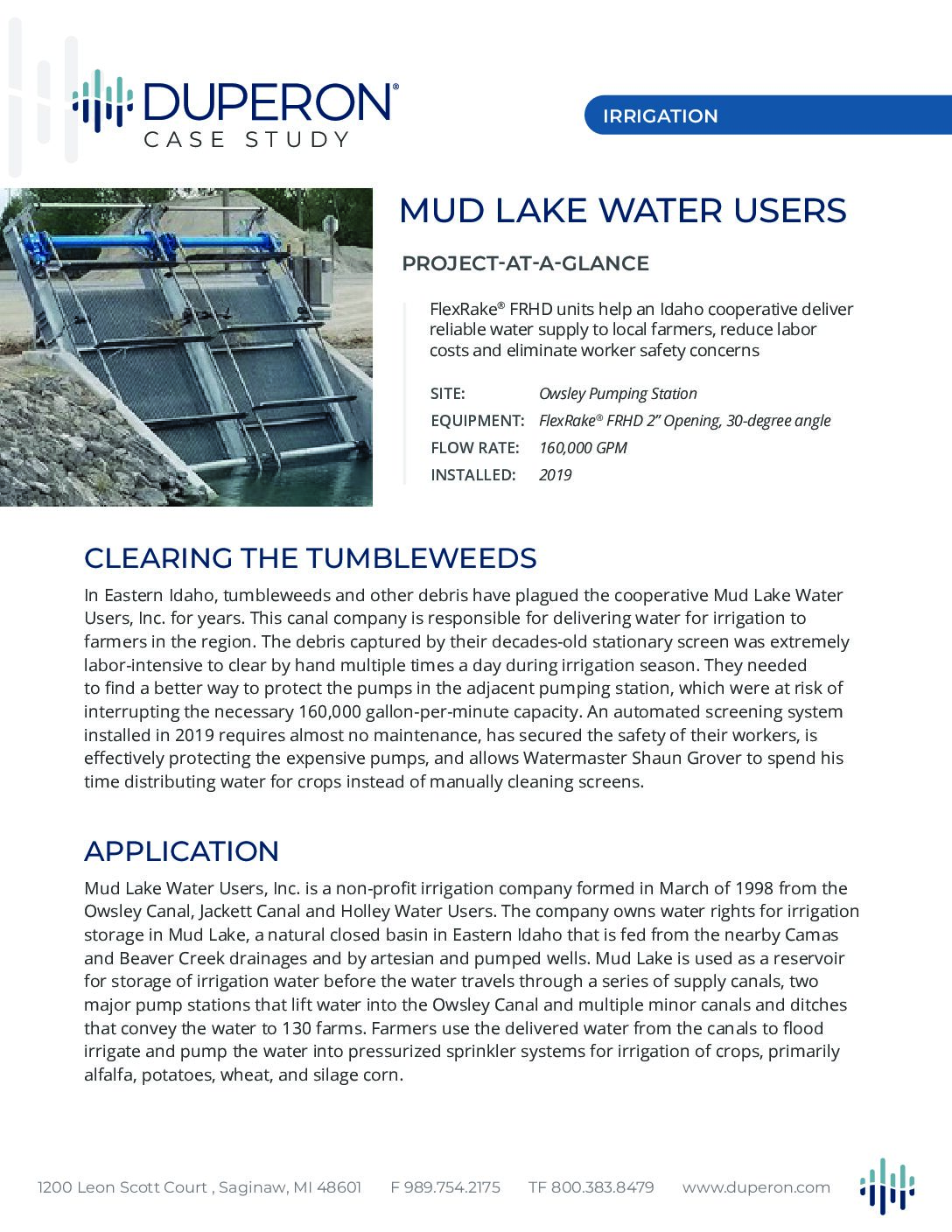

Mud Lake Water Users Case Study

FlexRake®FRHD units help an Idaho cooperative deliver reliable water supply to local farmers, reduce labor costs and eliminate worker safety concerns

St. Charles Parish Case Study

Duperon FlexRake® FRHD units operate flawlessly to keep Louisiana community above water during Hurricane Katrina and Rita

Related Products

Tell us about your project

‘You’ll like working with us’ is a commitment and way we deliver extraordinary customer care for the full life-cycle of your equipment. This is how we strive to earn the privilege to serve your continued screening needs.

Design Collaboration

To build your solution, our engineers take the time to understand your facility, process, and goals.

We’ll combine our team’s experience with water screening, cleaning, and processing with your team’s detailed understanding of your product and process, so we can develop a reliable and cost-effective solution.