Debris Management Technology

Washer Compactors and Conveyors

Complete Debris Management Solutions for Solids Handling and Transfer

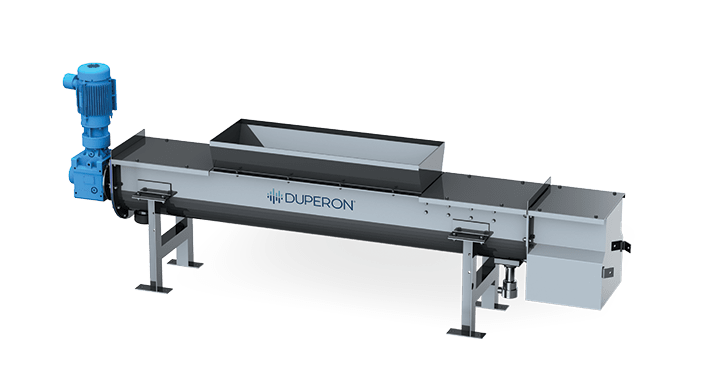

Shaftless Screw Conveyor

Fully-contained, compact wastewater conveyance for industrial and municipal wastewater

The Duperon® Shaftless Screw Conveyor uses a simple, compact, but powerful design to transport materials from the screen or washer compactor to a discharge point. With low energy costs and minimal maintenance, the Shaftless Screw Conveyor makes debris management easier across many different industrial, municipal and other wetted solids transport applications. Made from corrosion-resistant, stainless steel with UHMW pre-formed liners, the conveyor is made to withstand tough environments and work long hours. Customize the shaftless screw conveyor to suit your debris management needs by choosing the unit length, number of inlet hoppers, and discharge options.

Applications:

- Municipal Wastewater

- Industrial Applications

- And other wetted solids transport applications

Design Collaboration

To build your solution, our engineers take the time to understand your facility, process, and goals.

We’ll combine our team’s experience with water screening, cleaning, and processing with your team’s detailed understanding of your product and process, so we can develop a reliable and cost-effective solution.

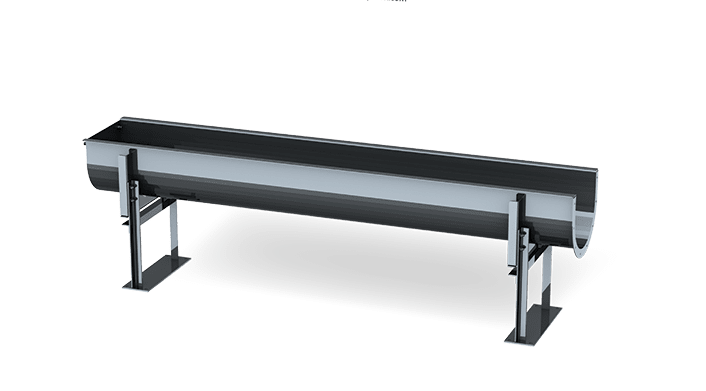

Sluice

Flexible Debris Management and Transfer for Any Application

For simple conveyance to transfer discharged screenings, the Duperon sluice offers a simple and reliable solution.With no belts, rollers, augers or other mechanical devices, the sluice demands very little maintenance and works in nearly any situation. In municipal applications, sluices typically discharge into washer compactors for dewatering. In other applications, such as flood control or raw water intakes, it may discharge downstream of the site or be transported to a bank or holding area. The simple, yet reliable design of the sluice integrates effectively with your new or existing debris management technology and facility equipment. With many customizable options, including pump size and volume, length, inlet feeds, trough capacity, and more, we can easily design a sluice that is right for your debris types, facility and application.

With over 35 years of experience, Duperon has implemented many sluices and we’ve mastered the distinctions across many industries and applications. We specially engineer each sluice to suit the needs of our clients and ensure that the sluice works reliably and effectively.

Applications:

- Municipal Wastewater

- Industrial Applications

- Stormwater and Flood Control

- Open Channel Intakes

- And other wetted solids transport applications

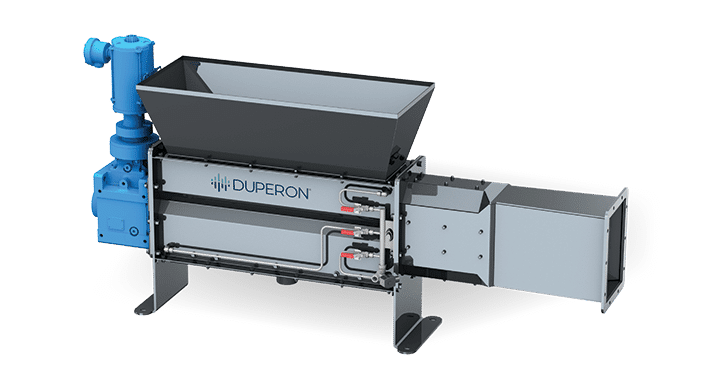

Washer Compactor

Powerful, Simple Debris Management Solutions for Variable Flow and Debris Conditions

The Duperon® Washer Compactor cleans captured screenings and makes debris management easier by reducing the weight, volume, and odors. With up to 84% volume reduction and 60% dry solids, the Washer Compactor helps municipal and industrial facilities minimize odor, meet hauler standards, and reduce landfill costs. While the Duperon® FlexRake® screens remove large debris, mats, and grease, the Washer Compactor removes the debris and completes the process by washing, compacting, transporting and bagging the discharged solids. The patented dual auger design provides positive displacement to prevent slipping, wrapping, clinging or bridging. The self-regulating compaction zone controls pressure, regardless of volume or friction, to deliver consistent compaction. Regardless of the flow or debris types, the rugged design of the Washer Compactor keeps working even when discharging rocks, grease, clothing, concrete, and metal up to 4 inches.

In addition, The Duperon Washer Compactor patent-pending Discharge Extension Option (DEO) can transport debris up to 40 feet in any direction, even vertically, eliminating the need for additional motor-driven conveyance systems. Unlike traditional debris management systems, the DEO option does not rely on a debris chute, friction or a high horsepower motor for compaction. The DEO option uses a unique design to create backpressure to dewater and compact debris. This eliminates the need for additional mechanical conveyance or large motors, making upkeep, installation and maintenance even easier.

APPLICATIONS:

- Municipal wastewater

- Combined sewer overflow

- Pump stations

- Lift stations.

- Industrial wastewater

- Other non-standard applications where debris is variable or difficult.

Tell us about your project

‘You’ll like working with us’ is a commitment and the way we deliver extraordinary customer care for the full life-cycle of your equipment. This is how we strive to earn the privilege to serve your continued screening needs.