Pulp & Paper

Screening Solutions

Reliable screening for intakes, process water recycling and wastewater treatment that serve the pulp and paper industry

Optimized water management for sustainable profitability

Water plays an essential role in the pulp and paper industry. A plant’s productivity and profitability have a direct correlation to its water usage and associated treatment costs. Duperon liquid/solids separation technologies help pulp and paper operations run smoothly and optimize water use.

- Since water is required for almost every part of the manufacturing process, it is critical that production has uninterrupted flow.

- As water is drawn from an intake (or recycled) it must be free of debris to avoid damaging downstream equipment and processes. Simple, reliable screening at the intake eliminates blinding and captures harmful debris ensuring consistent water supply for production.

- To reduce costs and their environmental impact, many pulp and paper facilities recycle their process water. To successfully do this, contaminants that were introduced in the manufacturing process must be removed before process water can be reused. Screens designed to efficiently separate liquid and solids increase plant productivity and maximize water reuse, providing a significant cost savings.

- Additionally, screening can recover pulp and fiber, increasing profitability by recovering valuable material from the waste stream and reducing disposal costs.

- Screening improves the efficiency of biological and chemical wastewater treatment processes that are often required to meet regulations, discharge permits and maintain environmental compliance.

- All of which allows you to focus your team and resources on production rather than treatment.

Duperon offers solutions for pump protection at intake screens, solids removal for process water reuse, and preliminary treatment for onsite wastewater for the pulp and paper industry. The simplicity of Duperon’s equipment translates into reliability, eliminating downtime, minimal maintenance, all while helping meet discharge compliance.

Applications

Duperon screens are designed to be simple and durable in order to perform in a variety of conditions. Materials of construction are selected to maximize the life of the equipment in extreme temperature and PH levels. Our simple designs can be applied to solve high organic loading, batch processing, and a wide range of flow conditions without significant manpower requirements in the following applications:

- Pulp and paper processing

- Particle board

- Paper recycling

- Milling

- Paper packaging

Solutions to address the following:

Duperon application engineers have listening down to a science. We will work with you to achieve your specific process goals, while bringing decades of liquid/solids separation experience to the conversation. Duperon screens can be used to solve a variety of pulp and paper processing to address the following:

- Coarse screening

- Intake screens

- Fine screening

- Preliminary wastewater treatment

- Resource recovery screens

- In-channel screening

- Piped-in screening

- Packaged screening solutions

- Pump protection

- Drum screens

- Conveyance

- Disinfection prescreening (Ozone, chlorine, UV, etc)

- Clarifier prescreening

- Aeration/settling pond prescreening

The Duperon®

Difference

Simple

With few parts and minimal maintenance, Duperon equipment is easy to install, own and operate by crew

Reduce treatment costs

Duperon screens optimize solids removal that lower BOD, COD, the amount of treatment chemicals needed and debris loading of downstream processes

Reliable

Designed to maintain critical operations without downtime

Low maintenance

Allows primary focus to remain on revenue-generating activities

Increased profitability

Recovering pulp and fiber for increased profitably that would otherwise be lost revenue and incur expenses for disposal

Responsive service

‘You’ll like working with us!’ is not just a slogan at Duperon, it’s a way of operating to deliver extraordinary customer care during your planned maintenance cycles and with strategic inventory agreements

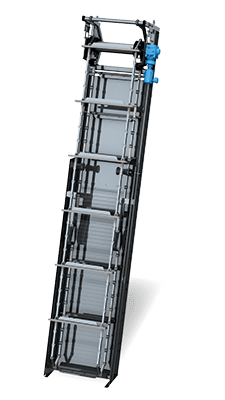

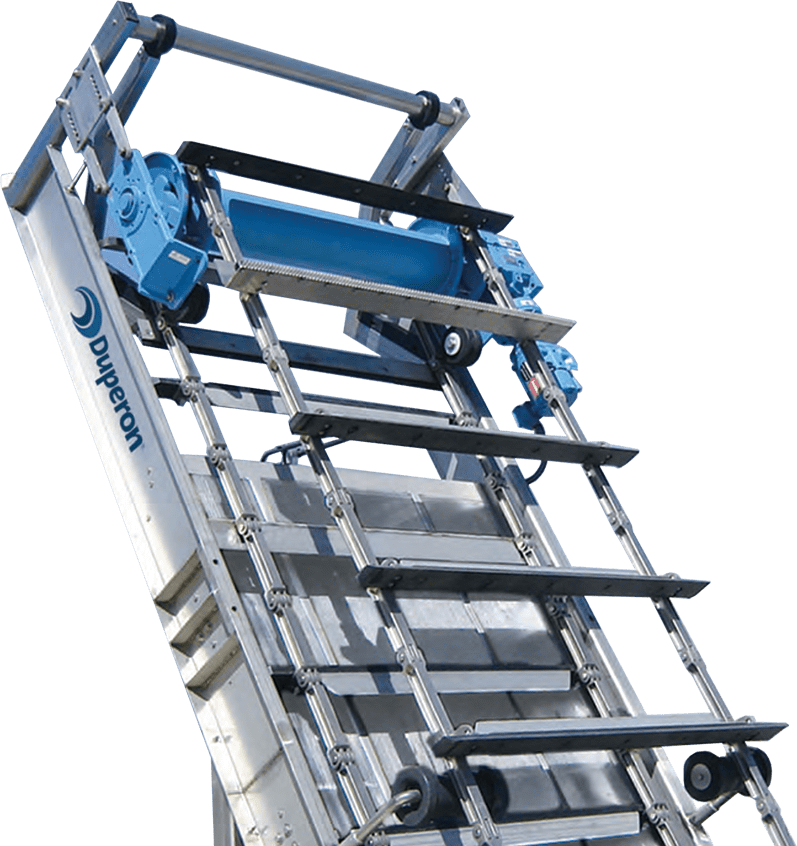

Coarse Screening

Bar openings greater than ½ in

Used for pump protection in raw water intakes

Fine Screening

Openings ½ in down to 0.020 in

Solids removal prior to process water recycling

Solids removal prior to clarification, aeration, and/or disinfection treatment

Solids recovery

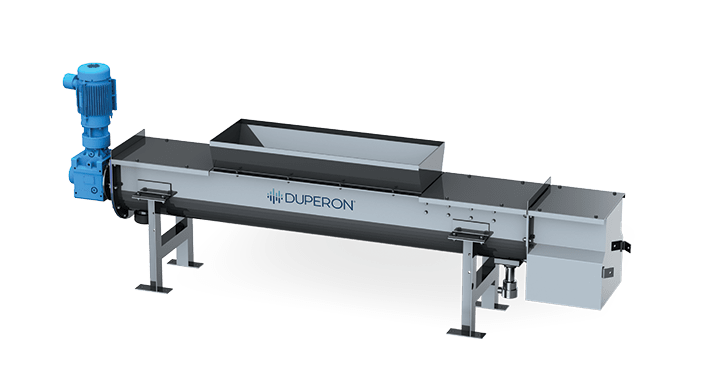

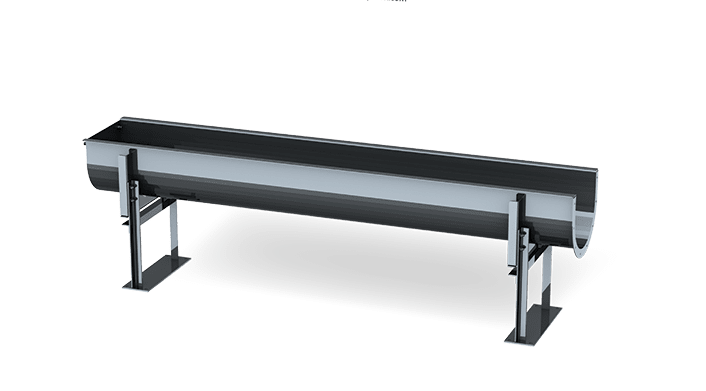

Debris Management

Collection and Conveyance

Processing and transport of collected screenings for disposal

Screening and Solids Handling Products

Screening and debris management products for industrial applications are designed to work continuously, reliably, and efficiently. A simple and effective design reduces maintenance and costs, keeping your operating expenses low.

Products quick guide

| Product Name | Screen Type | Bar Opening | Bar Type | Engineering |

|---|---|---|---|---|

| FlexRake® Fine Screen | Fine | 0.020 in to ⅛ in | Wedgewire, SSTL | Site Specific |

| FlexRake® IQ | Coarse & Fine | ⅛ in to 4 in | Slotted Bar, SSTL | Site Specific |

| FlexRake® Full Penetration Fine Screen | Fine | ¼ in to ½ in | Slotted Bar, SSTL | Site Specific |

| FlexRake® Full Penetration | Coarse | Greater than ½ in | Slotted Bar, SSTL | Site Specific |

| Package Screening System | Coarse & Fine | 0.020 to 2 in | Slotted Bar or wedgewire, SSTL | Site Specific |

| FlexRake® Heavy Duty | Coarse | 2 in – 4 in | Slotted Bar, A36 Steel, coated for intake. SSTL in wastewater | Site Specific |

Tell us about your project

Do you have a liquid/solids separation challenge in your collection system? We are here to help solve it.

Design Collaboration

To build your solution, our engineers take the time to understand your facility, process, and goals.

We’ll combine our team’s experience with water screening, cleaning, and processing with your team’s detailed understanding of your product and process, so we can develop a reliable and cost-effective solution.