Food & Beverage

Wastewater solutions

Providing reliable mechanical screening to reduce solids loading on secondary wastewater treatment

High-Quality Effluent Flows to the Bottom Line

Duperon helps customers achieve a high-quality effluent and reduces operating expenses in food and beverage wastewater processing.

- It begins with simple, reliable screening that handles the unique conditions of your plant, with minimal downtime or maintenance.

- By removing the bulk of the solids loading, it allows the downstream treatment processes to operate as it should; problem-free, reducing costs and ensuring uninterrupted production.

- Screening improves the efficiency of process water treatment to meet regulations, product quality demands and maintain environmental compliance.

- All of which allows you to focus your resources on production rather than treatment.

Reliably removing solids through screening is an effective strategy to reduce biological oxygen demand (BOD), fats/oils/greases (FOG) and other waste by-products. Screening can also reclaim materials for beneficial use that would otherwise undergo disposal or require costly additional treatment.

The simple design and durable materials of Duperon screens not only allows them to perform under a range of process demands such as high organic loading, batch processing, various debris, temperature, PH levels, and flow conditions but ensures a long product life.

Applications

Duperon proven screening technologies can be applied to a wide variety of food and beverage processes including:

- Breweries

- Bottling

- Dairies

- Frozen foods

- Fruit & vegetable processing

- Meat rendering

- Pet food

- Processed foods

- Soups & salsas

- Sugar processors

- Wineries

Solutions to address the following

Duperon engineers wastewater solutions for a wide variety of food and beverage processing plants. We work closely with you to understand your challenges and develop low-maintenance, long-term solutions. Our food and beverage screening solutions address the following:

- Coarse screening

- Fine screening

- Dissolved Air Flotation (DAF) prescreening

- Suspended Air Flotation (SAF) prescreening

- Moving Bed Biofilm Reactor (MBBR) prescreening

- Membrane Bioreactor (MBR) prescreening

- Aerobic and anaerobic biological treatment pre-screening

- In-channel screening

- Piped-in screening

- Packaged screening solutions

- Process pump protection

- Drum screens

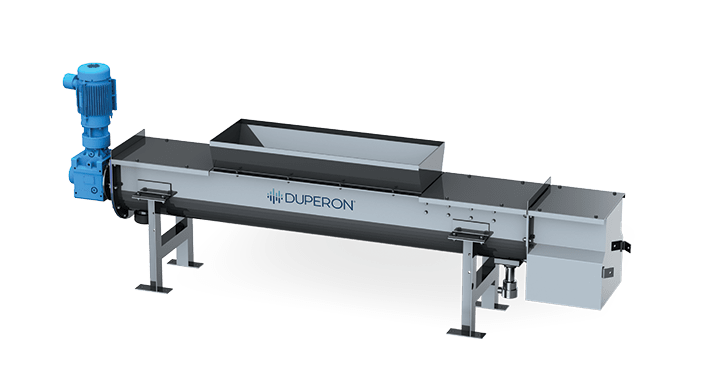

- Conveyance

The Duperon®

Difference

Simple

With few parts and minimal maintenance Duperon equipment is easy to install, own and operate by crew

Reduces treatment cost

Optimized solids removal lowers BOD, the amount of treatment chemicals needed and debris loading on downstream processes

Efficient

Uses low power consumption and little or no water

Reliable

Maintains critical operations without downtime

Low maintenance

Allows primary focus to remain on revenue-generating activities

Flexible

Duperon equipment adapts to a wide range of debris and flow variations

Partnership

‘You’ll like working with us’ is a commitment and way we deliver extraordinary customer care for the full life-cycle of your equipment. This is how we strive to earn the privilege to serve your continued screening needs

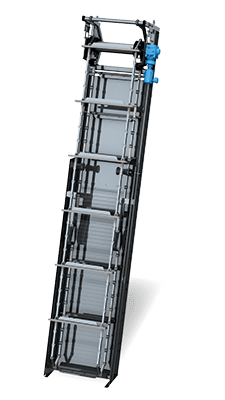

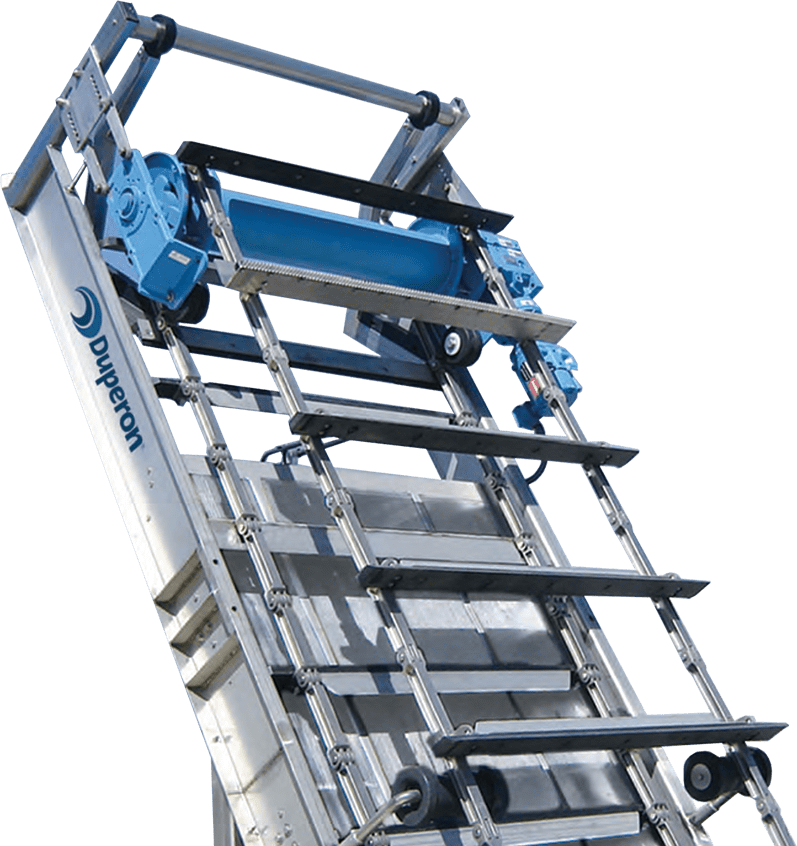

Coarse Screening

Bar openings greater than ½ in

Preliminary treatment screening for by-product removal

Fine Screening

Openings ½ in down to .020 in

Solids removal before flotation, clarification, filtration and/or biological treatment

Debris Management

Collection and Conveyance

Processing and transport of collected screenings

Food & Beverage Products

Our water treatment and screening systems for the food & beverage industry reduce the number of moving parts, simplifying maintenance and extending the life of your system. Our components work together as a complete system, or separately as needed.

Products quick guide

| Product Name | Screen Type | Bar Opening | Bar Type | Engineering |

|---|---|---|---|---|

| FlexRake® IQ™ | Coarse & Fine | ⅛ in to 4 in | Slotted Bar, SSTL | Site Specific |

| FlexRake® Full Penetration | Coarse | Greater than ½ in | Slotted Bar, SSTL | Site Specific |

| FlexRake® Full Penetration Fine Screen | Fine | ¼ in to ½ in | Slotted Bar, SSTL | Site Specific |

| FlexRake® Fine Screen | Fine | 0.020 in to ⅛ in | Wedgewire, SSTL | Site Specific |

| FlexRake® Fine Screen Boutique | Fine | 0.020 in to ⅛ in | Wedgewire, SSTL | Pre-Engineered |

| Package Screening System | Coarse & Fine | 0.020 to 2 in | Slotted Bar or Wedgewire | Site Specific |

Tell us about your project

Do you have a wastewater challenge at your food and beverage facility? Let our experts help you solve it.

Design Collaboration

To build your solution, our engineers take the time to understand your facility, process, and goals.

We’ll combine our team’s experience with water screening, cleaning, and processing with your team’s detailed understanding of your product and process, so we can develop a reliable and cost-effective solution.