Power Generation

Screening Solutions

Automated trash racks and trash rakes that deliver reliable water supply for power production

Maintains Consistent Water Supply for Power Generation

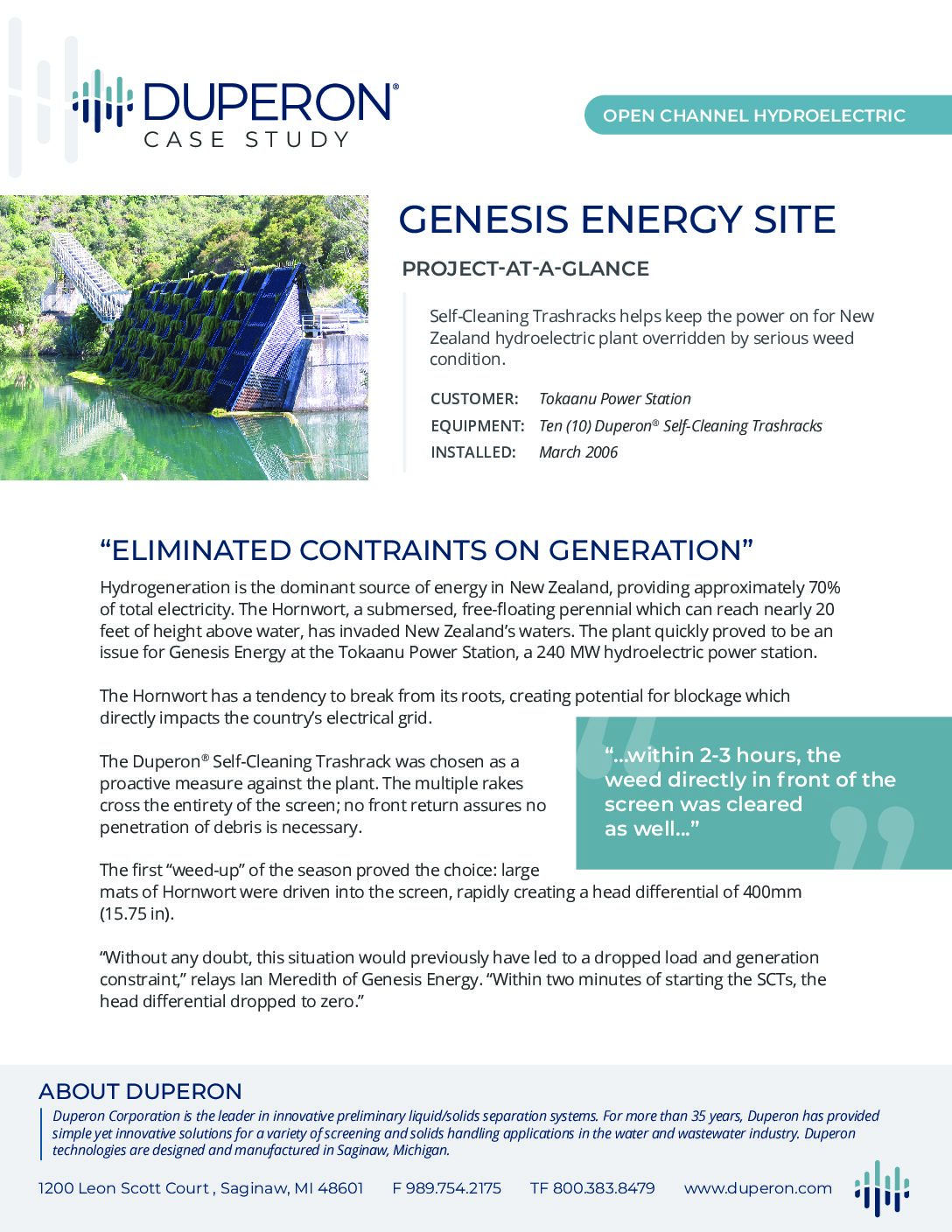

Water intakes for power generation often address conditions such as high volume, high velocity, large debris, human refuse, aquatic vegetation, seasonal foliage, or even marine life. Continuous cleaning equipment assures unrestricted water flow at the intake and protects downstream turbines, cooling towers, and traveling water screens from harmful debris. Duperon offers screening expertise and a range of systems to manage the unique demands of power intakes.

- Hydroelectric: Hydropower depends on water in motion to create electricity. As water is drawn from an intake it must be free of debris to avoid damage to the rest of the system. Trashrakes and screens help to remove debris, but ineffective screening can also restrict flow. This creates a delicate balance between the ability to screen out debris and minimize headloss to generate at full capacity.

- Thermoelectric: Cooling water intakes play an important role in thermal power generation. Many facilities use automated screening as a best practice to minimize debris events at their cooling towers. By preventing blockages at the intake, clients can avoid de-ration or shut down for greater system reliability and maximum power generation.

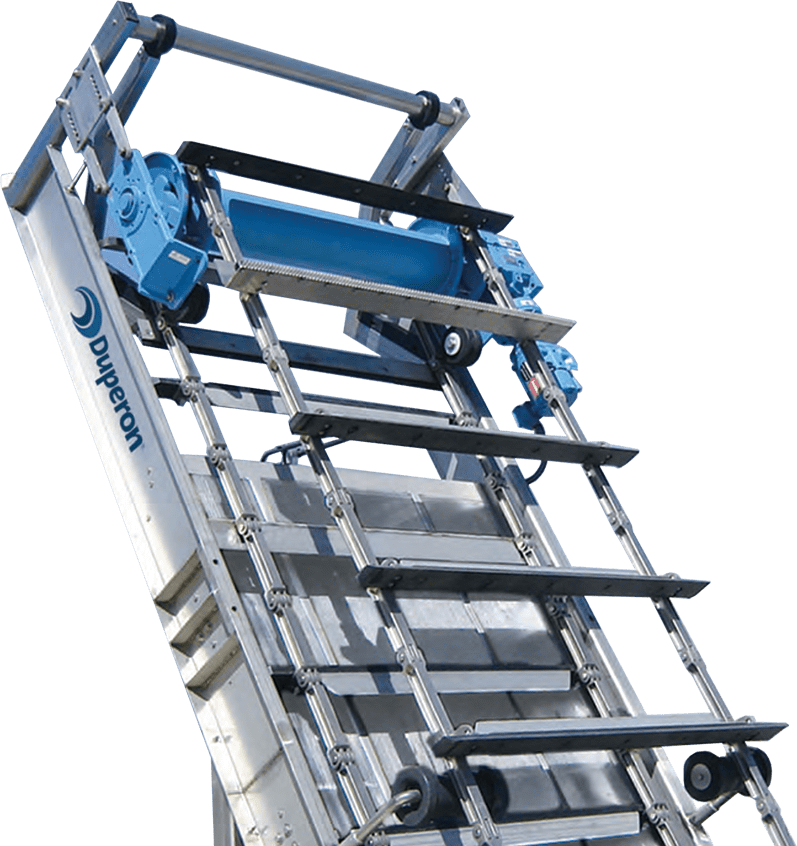

Duperon Full-Screen Cleaning™ cleans all of the screen, all of the time. It addresses debris as it comes in (and can be handled at the deck) and prevents accumulation to keep water flowing. Every cycle cleans the entire intake. This contrasts with transversing-style units that often have blinding that occurs before they can repeat their cleaning cycle, resulting in disrupted waterflow.

The simple design of Duperon screens allows it to reliably perform under a range of debris and flow conditions. The use of durable materials like A36 Steel (coated or hot-dipped galvanized), stainless steel or Super Duplex stainless ensure long product life in coastal and corrosive environments.

Applications

Duperon proven screening technologies can provide protection for a variety of thermal and hydroelectric power applications, including:

- Nuclear

- Coal

- Natural Gas

- Hydrogen

- Hydroelectric

Solutions to address the following

Duperon designs engineered solutions for a wide variety of power generation plants. We work closely with you to understand your challenges and develop low-maintenance, long-term solutions. Our screening solutions address the following:

- Coarse screens

- Fine screens

- Fish (and other wildlife) screens

- Bar screens

- In-channel screens

- Cooling tower screens

- Intake screens

- Trash rakes

- Trash racks

- Traveling water screens

The Duperon®

Difference

Simple

With few parts and minimal maintenance Duperon equipment is easy to install, own and operate by crew

Consistent Water Supply

Continuous cleaning reduces risk of headloss or intake screen blockage to provide flow to turbines

System Reliability

Designed to maintain critical operations without downtime or loss of power generation

Low Maintenance

Allows primary focus to remain on revenue-generating activities

Flexible

Duperon equipment adapts to a wide range of debris and flow variations

Wildlife-Friendly

Manatee Safe designation from the US Army Corps of Engineers (USACE), US Fish & Wildlife Services (FWS) and Florida Fish and Wildlife Conservation Commission (FWC)

Cost-Effective Retrofit

Mount a Duperon raking device on an existing stationary trashrack to save money and avoid large infrastructure upgrades

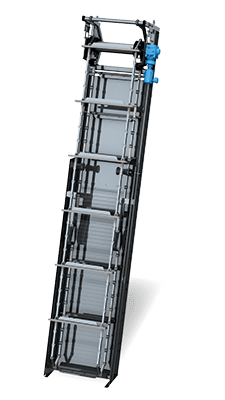

Coarse Screening

Bar openings greater than ½ in

Automated trashracks and trashrakes

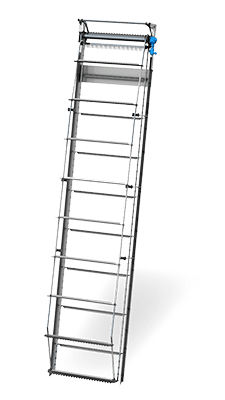

Fine Screening

Openings ½ in down to 0.020 in

Small solids removal, fish screening in accordance with section 316(b) of the Clean Water Act

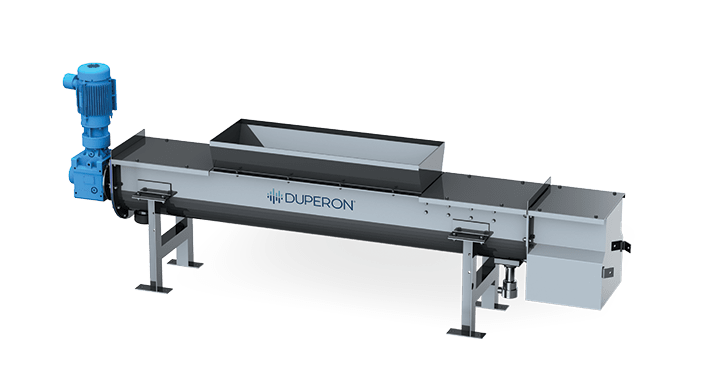

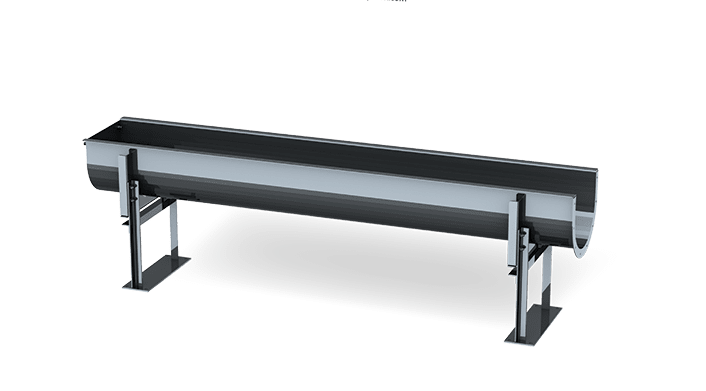

Debris Management

Collection and Conveyance

Processing and transport of collected debris

Power Generation Products

Power generation screens and trash rakes must be adaptable and durable, but also designed to minimize headloss, and remove debris to maintain optimum flow. With the ability to handle high volume, velocity, and challenging debris, these systems continue to work under normal or extreme conditions.

Products quick guide

| Product Name | Screen Type | Bar Opening | Bar Type | Engineering |

|---|---|---|---|---|

| Self-Cleaning Trashrack | Coarse | 2 in – 3 in | Slotted Bar, A36 Steel coated. SSTL options available | Site Specific |

| FlexRake® Heavy Duty | Coarse | 2 in – 4 in | Slotted Bar, A36 Steel coated or hot-dipped galvanized. SSTL options available | Site Specific |

| FlexRake® Rake Only | Coarse & Fine | Uses existing trash rack or wedgewire screen | Uses existing trash rack or wedgewire screen | Site Specific |

| FlexRake® Full Penetration | Coarse | Greater than ½ in | Slotted Bar, SSTL | Site Specific |

| FlexRake® Fine Screen | Fine | 0.020 in to ⅛ in | Wedgewire, SSTL | Site Specific |

Downloads

Case Studies

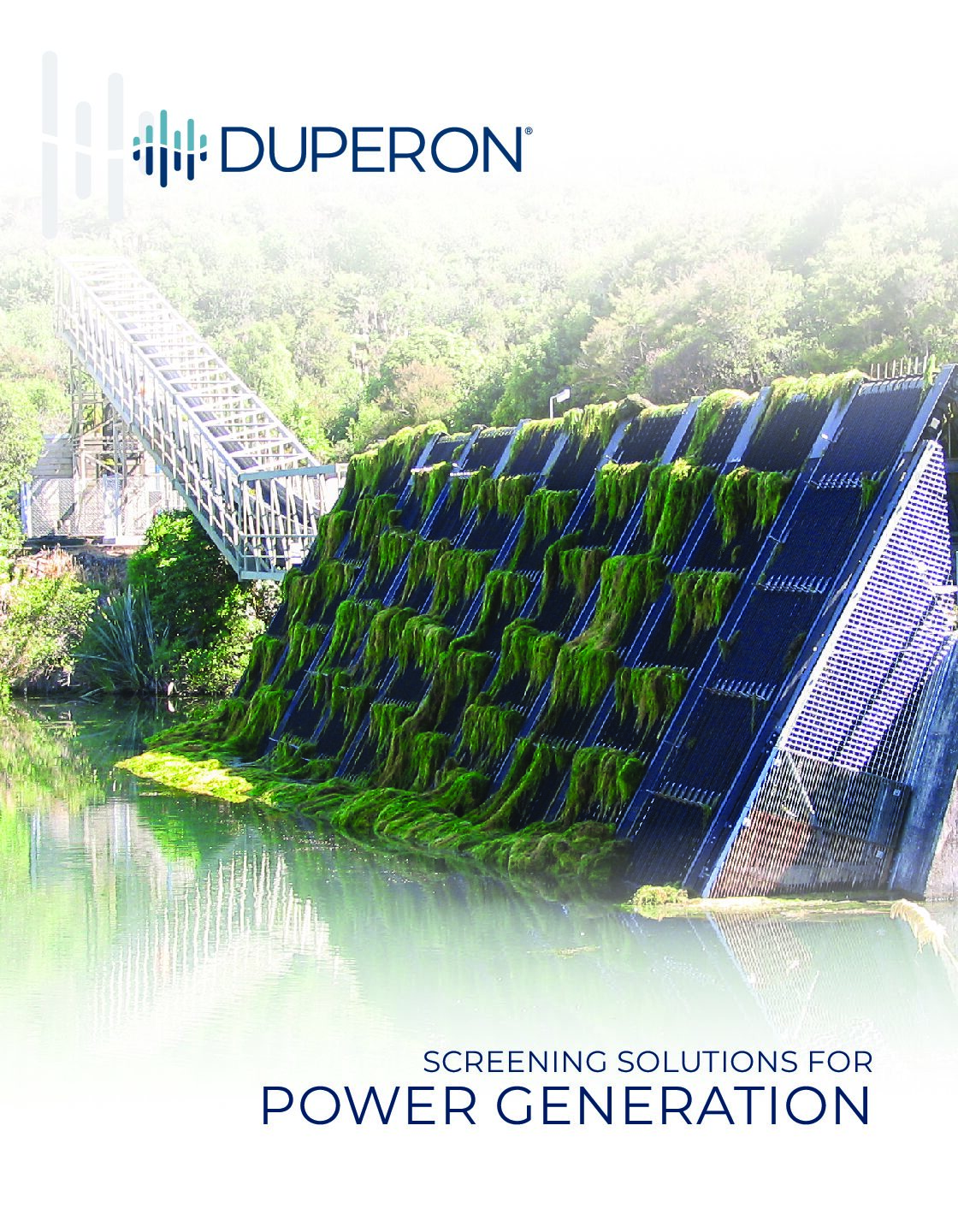

Genesis Energy Case Study

Self-Cleaning Trashracks helps keep the power on for New Zealand hydroelectric plant overridden by serious weed condition

Tell us about your project

Do you have a screening challenge at your power generation facility? Let’s solve it together.

Design Collaboration

To build your solution, our engineers take the time to understand your facility, process, and goals.

We’ll combine our team’s experience with water screening, cleaning, and processing with your team’s detailed understanding of your product and process, so we can develop a reliable and cost-effective solution.