Internally Fed

Drum Screen

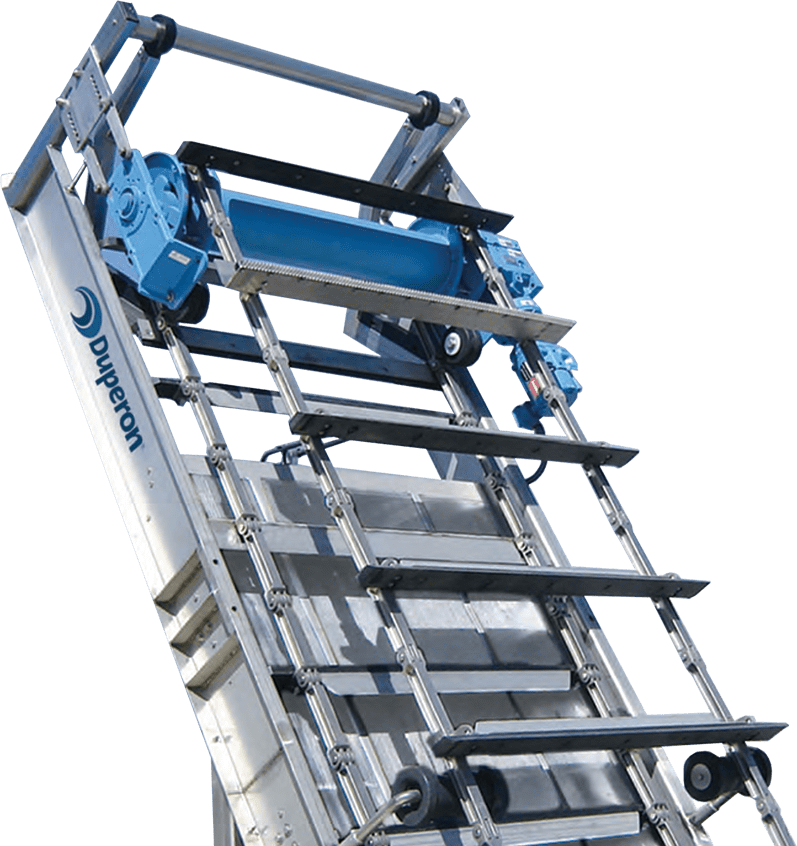

We didn’t reinvent the wheel. We removed it. An innovative drum screen design without trunnion wheels.

Introducing the Duperon® Drum Screen

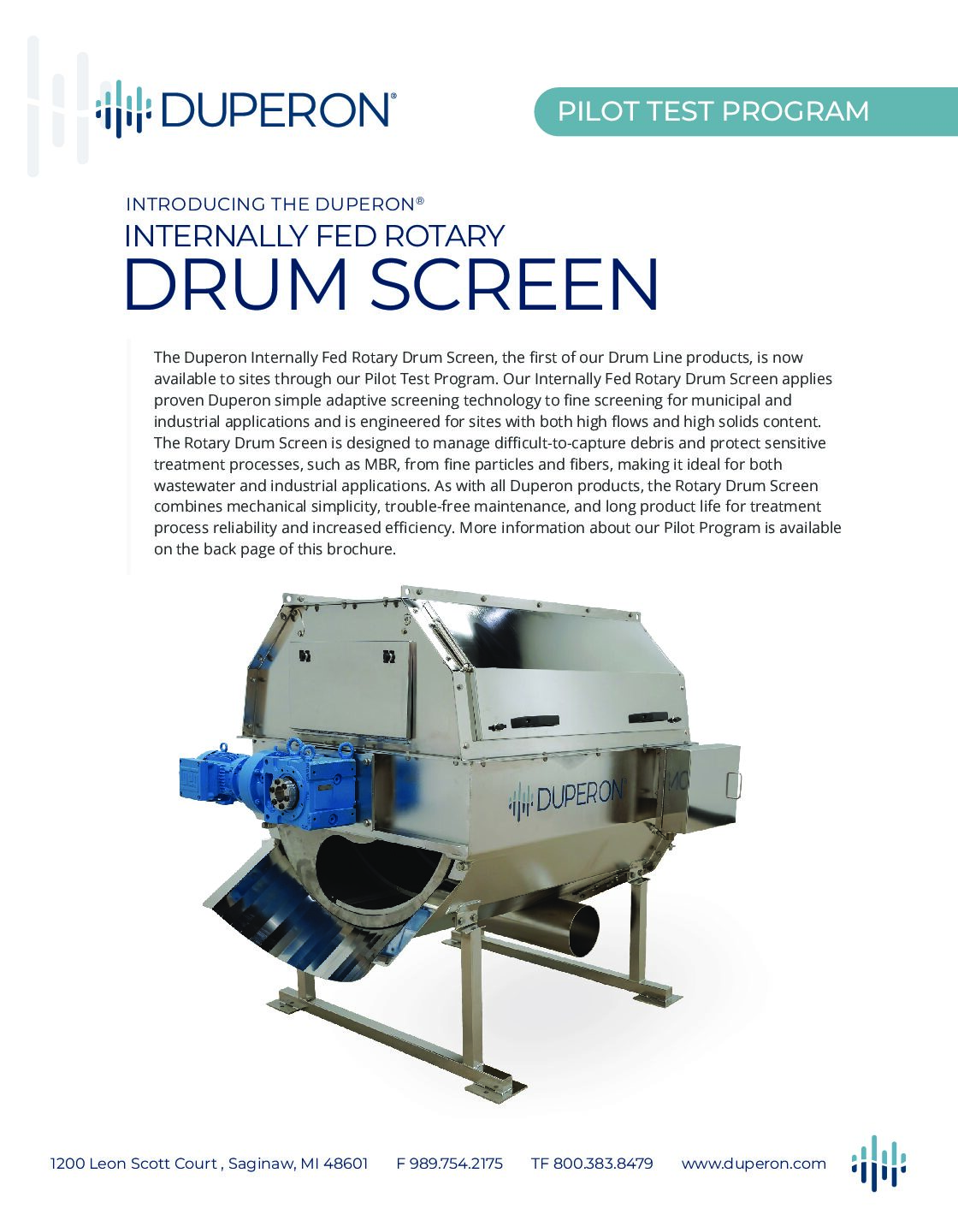

The Duperon Internally Fed Rotary Drum Screen, the first of our Drum Line products, applies proven Duperon simple adaptive screening technology to fine screening for municipal and industrial applications. Engineered for sites with both high flows and high solids content, the Duperon Drum Screen is designed to manage difficult-to-capture debris and protect sensitive treatment processes, such as MBR, from fine particles and fibers, making it ideal for both wastewater and industrial applications. As with all Duperon products, the Duperon Drum Screen combines mechanical simplicity, trouble-free maintenance, and long product life for treatment process reliability and increased efficiency.

The Duperon Internally Fed Rotary Drum Screen is only available to sites through our Pilot Program. Learn more about our Pilot Program here.

Applications:

- Wastewater with MBR

- IFAS

- MBBR

- Pulp and Paper Mills

- Food and Beverage

- Vegetable processing

- Meat processing

The Duperon®

Difference

The Duperon®

Internally Fed Rotary Drum Screen

Long product life

The unique design eliminates the need for trunnion wheels, sprockets and chains, which reduces the wear and tear points and increases the product’s lifespan.

Trouble-free maintenance

All routine maintenance is done at chest level. Removal of the drum is not required to perform maintenance and manual clean in place (CIP).

Designed for duty

Engineered to perform in fine screening applications that have high flows and high solids loading.

Flexible design

Quick change-out screening panels available in various opening sizes, allows for improved debris management.

Low cost of ownership

With few wear parts, a fractional horsepower motor and minimal maintenance required, Duperon equipment is easy to install, own, and operate.

Customizable

The water inlet can be designed on either side of the drum screen, providing options for difficult installation scenarios.

Description

The Duperon Internally Fed Rotary Drum Screen utilizes a direct drive system to eliminate the use of belts, chains or sprockets. A combination of stainless-steel shoes and UHMW polyethylene wear strips replace the use of trunnion wheels reducing labor intensive maintenance. The screening panels remove easily for regular cleaning and to allow access inside the drum without disassembling the machine.

Screening panels are available in wedge wire, perforated plate and wire mesh in various opening sizes to optimize debris removal.

Pilot unit specifications

| Unit Width | 58″ |

| Unit Length | 69″ |

| Panel Type | Wedge wire, perforated plate, and wire mesh |

| Openings | 2mm |

| Materials of Construction | Available in 304 SSTL |

| Spray Bars |

Standard 1 |

| Typical Motor | 1 hp |

| Cleaning Frequency | Continuous |

| Drum Rotation Speed | 4-5 rpm |

| Flow Capacity | TBD based on test. Estimates can be provided. |

| Standard Controls | TBD based on test. Estimates can be provided. |

| Typical Applications | WWTP with MBR, industrial applications, IFAS, MBBR |

| Operation Options | Continuously/manual, automatic with timer, float, SCADA, differential/high-level sensing options with I/O as needed |

Photo Gallery

Case Studies

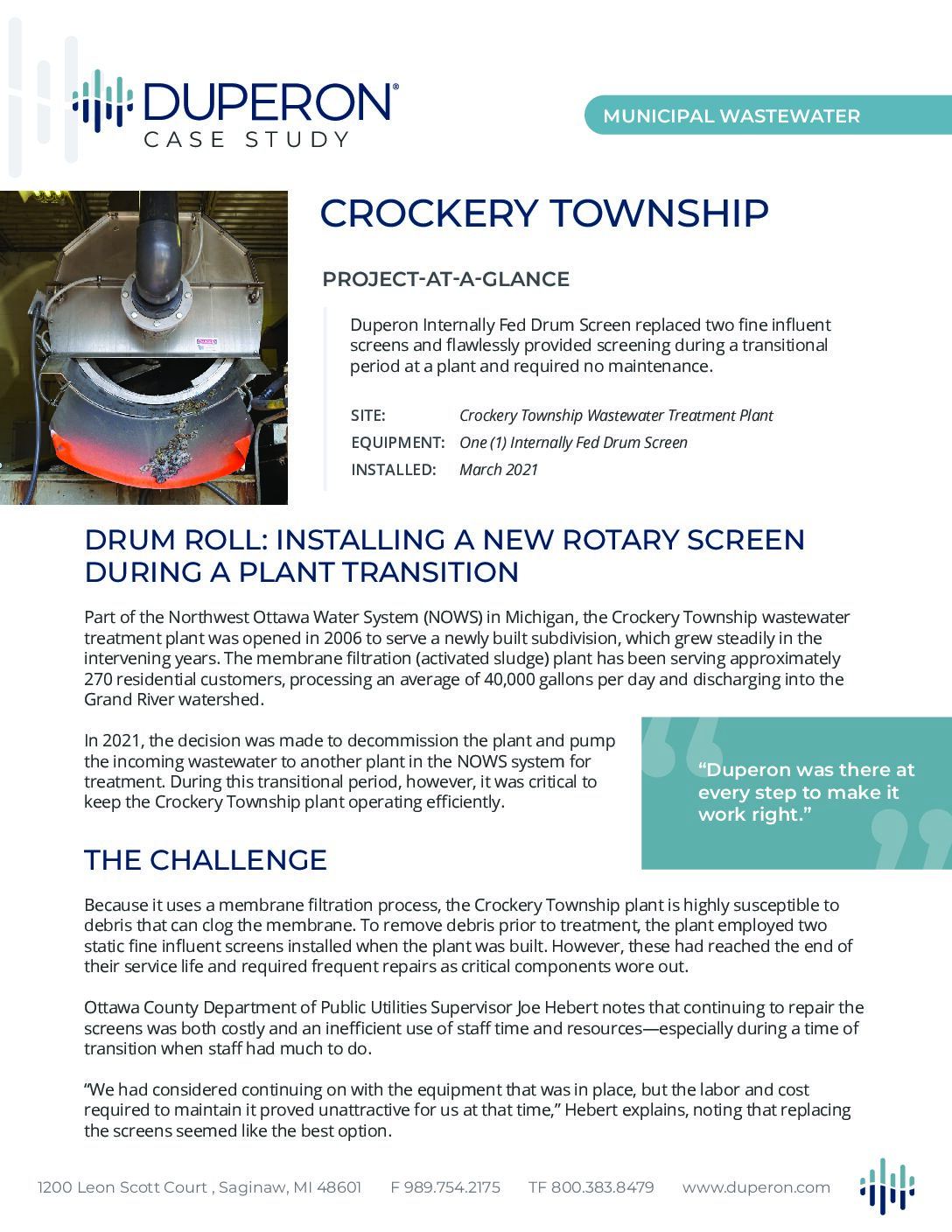

Crockery Township Case Study – Internally Fed Rotary Drum Screen

Duperon’s Internally Fed Drum Screen replaced two fine influent screens and flawlessly provided screening during a transitional period at a plant and required no maintenance.

Join the drum screen pilot program

Try out the Duperon® Drum Screen at your site with our Pilot Test Program. Both municipal and industrial sites may participate in this 2-6 week program to gain valuable information on the type and volume of debris your site manages.

Our portable, skid-mounted Drum Screen system comes with controls and multiple screen panel options.

Duperon will deliver and assist with the set-up of the Drum Screen, provide operational training, sampling assistance, analysis of sample data, and a final test report. The data derived from the sample tests provides valuable information to ensure your site has the screening system in place to provide system-wide resiliency.

To learn more about the Duperon Drum Screen Pilot Program, complete the form below or contact us at sales@duperon.com.

The Drum Screen is expected to be fully field tested by March of 2024 and available to all Duperon customers by that summer.

Design Collaboration

To build your solution, our engineers take the time to understand your facility, process, and goals.

We’ll combine our team’s experience with water screening, cleaning, and processing with your team’s detailed understanding of your product and process, so we can develop a reliable and cost-effective solution.