FlexRake IQ2®

Maximum Resiliency

Smart Raking™ and Smart Bar Screen™ provide additional hydraulic capacity and safety factor for maximum resiliency

A smarter way to screen

Today’s extreme weather conditions, changing populations, and new solids like flushable wipes, have added stress on plant operations. Peaking events are higher and more frequent than they have ever been. When planning, engineers must consider all the known (and account for unknown/changing) debris and flow variables. Design safety factors ensure the headworks can manage the highest possible flow, sometimes resulting in more infrastructure like extra units, bypass channels, oversized equipment, and coarser bar openings to handle these peaking events.

We asked ourselves, what if the headworks could be installed with the finest possible openings for normal flows and the screen itself adapted to peak events?

The answer? An intelligent screening system that knows what to do and when to do it.

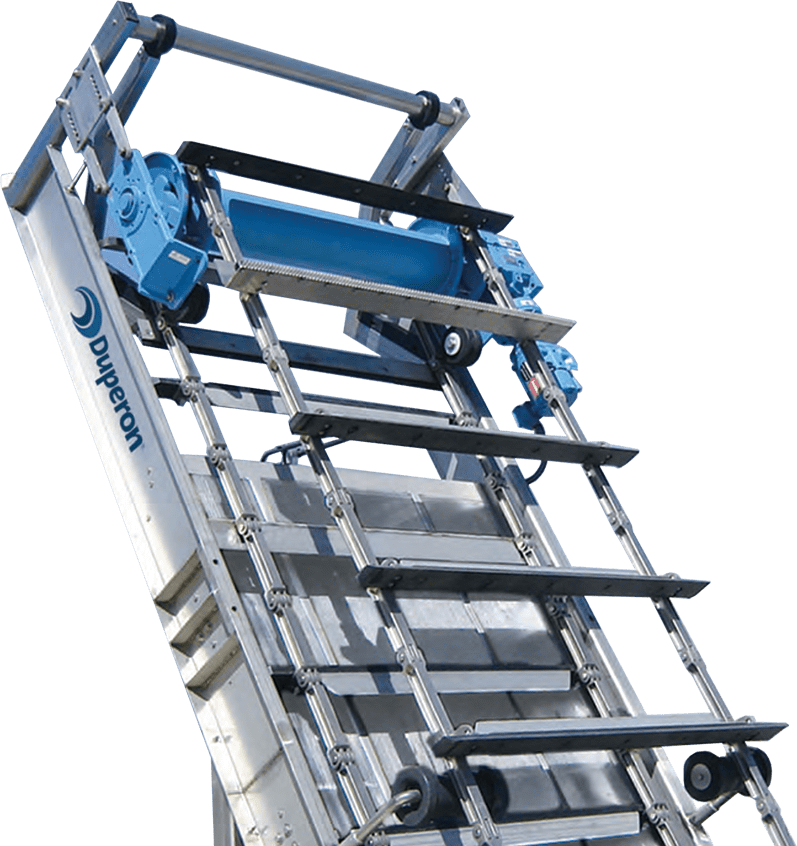

INTRODUCING the FlexRake IQ2®

A screening system that allows fine screening during normal conditions, then automatically transitions to a wider opening during peak conditions. The FlexRake IQ2 has all the enhanced raking features of the FlexRake IQ with the Smart Bar Screen™ upgrade for additional hydraulic capacity when it’s needed most.

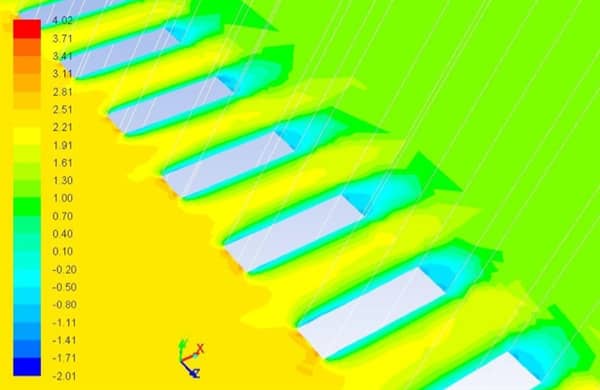

Like the FlexRake IQ, the FlexRake IQ2 significantly improves solids handling by sensing conditions and speeding up to accommodate changing debris and flow. The reconfigured geometry of design allows for lowest possible engagement to better handle settled solids. Re-engineered scrapers are stronger and remove up to 4x more debris. The re-imagined FlexLink still manages large debris without jamming and now re-engages into the bar screen faster. For optimum performance under all conditions, the next-level FlexRake IQ2 intuitively transforms the bar screen to accommodate increased flow capacity…without operator intervention.

The FlexRake IQ2 provides additional resilience with TWO SCREENS IN ONE for the safety factor of a coarse screen combined with the debris capture of a fine screen… intuitively & automatically

- Screen at the finest bar opening during normal plant operations.

- Manage hydraulic and solids surges by adapting bar opening as flows demand more capacity

- Return to finest screen openings all without operator interface

The FlexRake IQ2: physically and operationally adapts for maximum resiliency over the broadest range of conditions.

Applications:

- Pump stations

- Influent bar screens

- Municipal headworks

- Combined sewer overflow facilities

- Industrial applications

The Duperon®

Difference

The Duperon

FlexRake IQ2

The FlexRake IQ2 includes all the Smart Raking™ benefits of the FlexRake IQ

Automated, real-time response

Intuitive Sequence of Operations optimizes screen field in changing flow and debris conditions

Increased debris removal

Up to 4x the debris removal capacity

Enhanced solids capture

Improved grit/rock handling and rapid re-engagement into the bar screen after removing large debris

The FlexRake IQ2 provides maximum resiliency for peak flow management with the Smart Bar Screen™:

Maximum capture

Screens to the finest bar opening for normal operations and transforms to larger openings as required – matching the best capture rate for the flow rate in real-time

Additional throughput and safety factor during peak flow

40% increased hydraulic capacity when bar screen transforms to a wider opening

Simple operation

The screen field is monitored for constant optimization without operator intervention

Maintains screened flow

No process interruption with continuous cleaning during the open and close cycle between fine and larger openings

Upgrade existing sites to finer openings

May allow for finer openings on existing sites while accommodating peak flows

Description

A new level of resiliency is required to meet today’s plant challenges and prepare for tomorrow’s unknowns. The FlexRake IQ Platform tackles high peaking factors due to extreme weather and menacing debris like “flushable” wipes, first flushes and settled solids. This is accomplished by system improvements and a patent-pending sequence of operations that automatically responds in real-time to optimize the screen field.

The re-imagined design of the FlexRake IQ focuses on smart enhancements to the raking device to manage heavy solids loading events with 4x increased debris removal capacity, improved grit and rock handling, and greater solids capture. During peak flow conditions, the FlexRake IQ2 adjusts the bar screen opening itself to provide additional hydraulic capacity and safety factor. Matching the best capture rate to the flow volume in real- time.

The FlexRake IQ Platform is an intelligent screening system that knows what to do, and more importantly when to do it without operator intervention.

General Specs

| Typical Applications & Key Considerations |

Other site considerations:

|

| Unit Width | 2 ft to 6 ft |

| Unit Length | Up to 50 ft with a maximum of three IQ2 panel |

| Bar Openings | ¼ in or greater |

| Angle of Installation | Vertical to 45 degrees |

| Material of Construction | Standard 304 SSTL. 316 SSTL available |

| Typical Motor | 1 hp |

| Cleaning Frequency | Entire screening field cleaned every 7 seconds at max speed |

| Standard Controls | Base package will include ultrasonic differential/high level sensing so it can adjust Smart bar screen™ dependent on water levels in the channel |

Key Features

Patent-pending Smart LogIQ™ Sequence of Operations: Intelligently monitors and automatically adjusts screen operations to changing channel conditions

Smart Bar Screen™: Physically transitions into a larger bar opening when needed to allow additional flow throughput and safety factor in peaking events

Patent-pending re-engineered FlexLink™: designed for additional speed capabilities

Rapid re-engagement: removes large/irregular debris without shutdown and quickly returns the scraper into the bar screen to keep it clean

Re-engineered scraper design: provides 4x debris removal capacity and increased strength

Re-configured bar screen design: allows for lowest possible engagement and improved grit/rock and settled debris handling

All the benefits of the Original FlexRake platform

- Reliable

- Jam Evasion™ Technology

- Low maintenance

- Adaptable to debris

- Low cost of ownership

- Over 25 years of application experience

- Learn more

Schematic

Photo Gallery

Case Studies

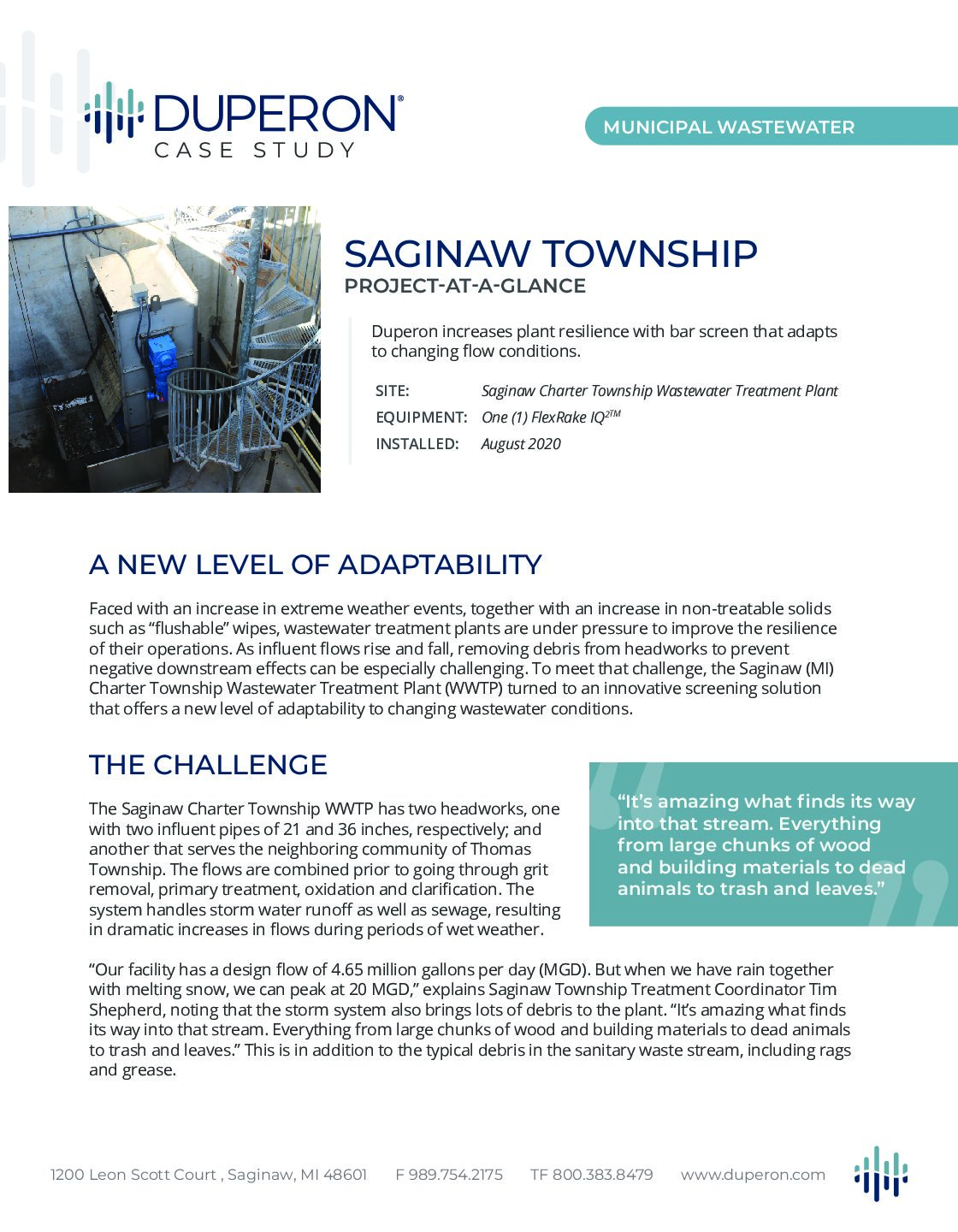

Saginaw Township Case Study – FlexRake IQ²™

Duperon increases plant resilience with bar screen that adapts to changing flow conditions.

Related Products

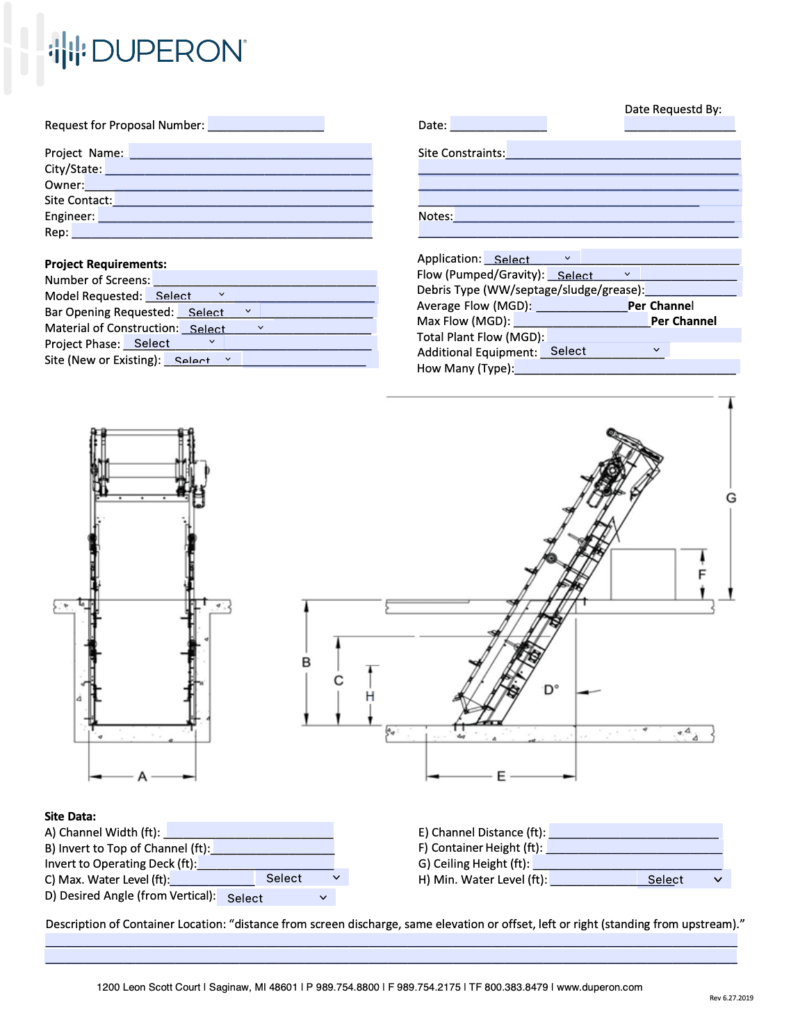

RFQ form

Tell us about your project

‘You’ll like working with us’ is a commitment and the way we deliver extraordinary customer care for the full life-cycle of your equipment. This is how we strive to earn the privilege to serve your continued screening needs.

Design Collaboration

To build your solution, our engineers take the time to understand your facility, process, and goals.

We’ll combine our team’s experience with water screening, cleaning, and processing with your team’s detailed understanding of your product and process, so we can develop a reliable and cost-effective solution.