FlexRake® FS

Fine Screen

openings from 0.020 in to 0.125 in

The advantage of FlexRake® Adaptive Technology™ for specialized fine screen applications

Fine screening at its finest

The FlexRake® Fine Screen (FS) model provides a T-shaped Wedgewire screen that can filter from 0.020 to 0.125 inches. The FlexRake FS is ideal for water intakes, fish screening and industrial applications that require fine filtration.

The FlexRake has evolved to meet the requirements of multiple industries. Wherever applied, it is a workhorse that just keeps running. The inherent value of the FlexRake is its simplicity: long product life, low cost of ownership, and adaptability to a range of site conditions (varied flows, debris types, and volumes).

The adaptability of the FlexRake manages both unusual and large debris, as well as process peaks. Its ability to operate across the intake with a slow and continuous movement assures no fish impingement against the screen. Whether environmental protections or bottom-line profitability improvements are your objectives, the FlexRake Fine Screen model may be the option when the screening needs to be fine.

Open channel applications

- Water intakes

- Reservoir protection

- Fish screening

- Beautification screening

Industrial screening applications

- Wineries

- Food processing

- Other food and beverage

The Duperon®

Difference

The Duperon®

FlexRake® FS

Simple

With few parts and minimal maintenance Duperon equipment is easy to install, own, and operate

Flexible design

Adapts to a range of known conditions and unpredictable debris and flow variations

Efficient

Uses fractional horsepower with low energy consumption (solar power options available)

Customizable

Engineered to fit the unique needs of your site or treatment process

Reduces treatment costs (for industrial applications)

Effective fine solids removal lowers BOD (biological oxygen demand), the amount of treatment chemicals needed, debris loading on downstream processes or surcharges for high-strength wastewater

Wildlife-friendly (for fish and intake screening)

Manages fish screening velocity requirements to avoid impingement. The FlexRake® received Manatee Safe designation from the US Army Corps of Engineers (USACE), US Fish & Wildlife Services (FWS) and Florida Fish and Wildlife Conservation Commission (FWC)

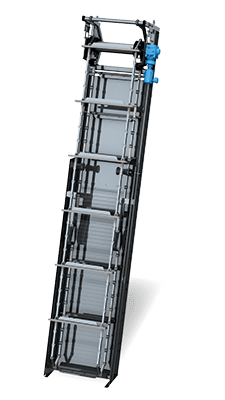

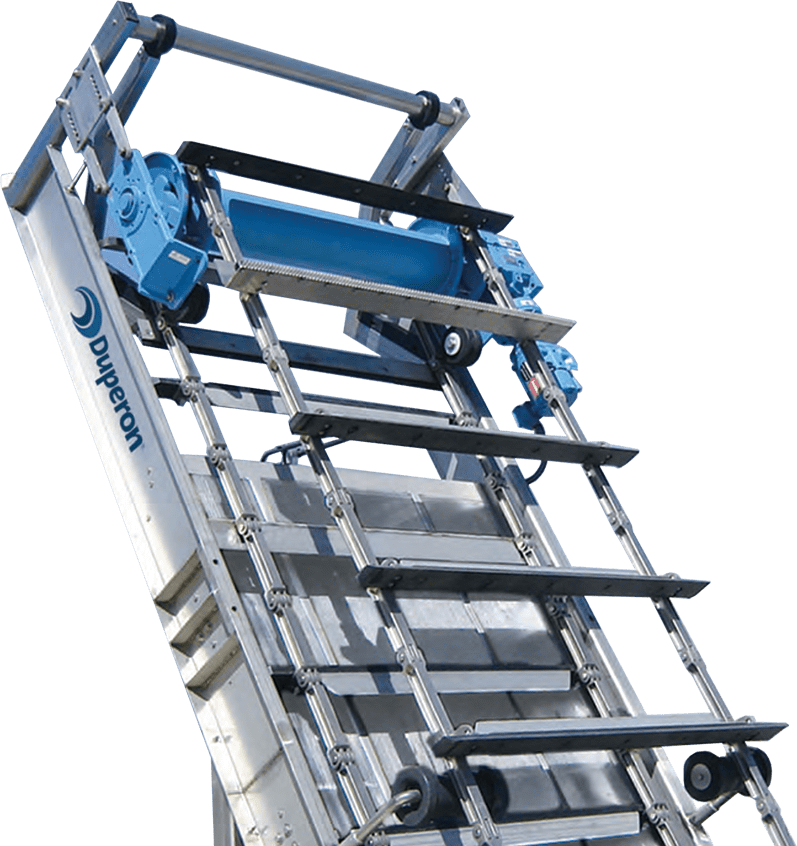

Description

The FlexRake® FS is a front-clean, front-return, mechanically cleaned bar screen. It features the industry-leading FlexLink™ multifunctional link system, which eliminates underwater sprockets, bearings or tracks that create a fixed path of travel and are subject to fouling and/or jamming. The groundbreaking flex/pivot action of the Duperon FlexRake is unhampered by large debris.

The FlexRake FS is a fine screen that utilizes stainless steel wedgewire with scraper configuration options consisting of beveled edges, squeegees, or brushes depending on the application. Wedgewire openings range from 0.020 inches to 0.125 inches.

General Specs

| Typical Applications |

|

| Unit Width | 2 ft to 12 ft

Single strand unit available 18 in to 24 in |

| Unit Length | 10 ft to 50 ft |

| Wedgewire Openings | 0.020 in to 0.125 in |

| Scraper Configuration | UHMW scrapers consist of squeegees, beveled edges or brushes depending on application |

| Material of Construction | Available in 304 or 316 Stainless Steel |

| Flow Capacity | Designed to your site and velocity requirements |

| Cleaning Frequency | 1 discharge/minute on low

4 discharges/minute on high |

| Lifting Capacity | 1000 lbs |

| Angle of Installation | 15 to 45 degrees from vertical, dependent upon site conditions |

| Typical Motor | ½ hp inverter duty, explosion proof |

| Standard Controls | Packages range from simple start/stop to sophisticated automation.

Motor overload protection provided. |

| OPERATION OPTIONS | Continuous/Manual

Automatic with timer, float, SCADA, differential/high-level sensing options with I/O as needed |

Key Features

- Industry-leading FlexLink™ eliminates lower sprockets, submerged bearings and tracks

- FlexLink multifunctional link system has ultimate strength of 60,000 lbs with unmatched durability

- Full-Range Flexibility adapts to debris variations from human refuse, algae, tree branches to food processing byproducts.

- Jam-Evasion™ Technology lifts or pivots to process large debris without shutdown or jamming

- Slow operating speed ensures that wild and aquatic life are unharmed

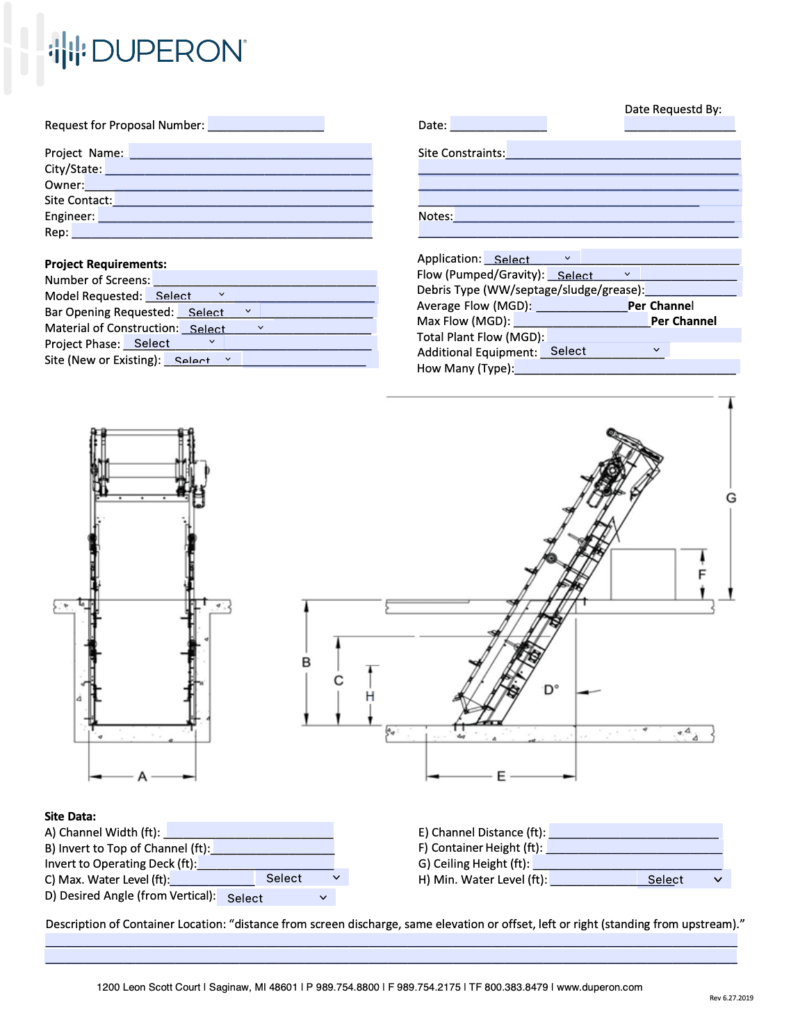

Schematic

Photo Gallery

Case Studies

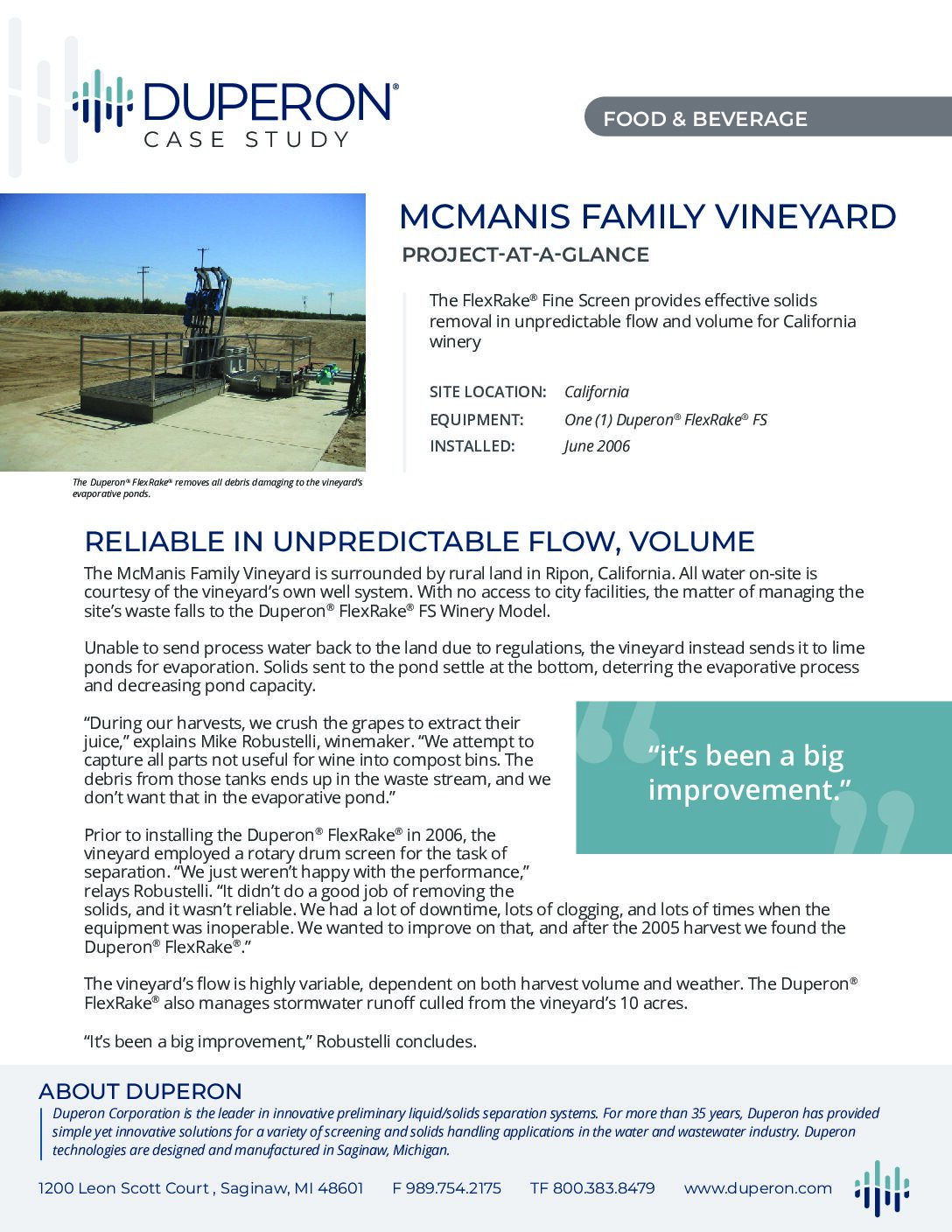

McManis Family Vineyard Case Study

The FlexRake® Fine Screen provides effective solids removal in unpredictable flow and volume for California winery

Related Products

RFQ form

Tell us about your project

‘You’ll like working with us’ is a commitment and the way we deliver extraordinary customer care for the full life-cycle of your equipment. This is how we strive to earn the privilege to serve your screening needs.

Design Collaboration

To build your solution, our engineers take the time to understand your facility, process, and goals.

We’ll combine our team’s experience with water screening, cleaning, and processing with your team’s detailed understanding of your product and process, so we can develop a reliable and cost-effective solution.