City of St. Joseph

Case Study

Project-at-a-glance

Stainless-steel, rust-resistant Fabricated Drive Head installed on a 10-year old FPFS, reducing operating costs.

SITE: South Side Industrial WTF

EQUIPMENT: (1) Fabricated Drive Head

INSTALLED: 2022

New Drivehead Reduces Cost And Maintenance

The South St. Joseph Industrial Sewer District in St. Joseph, MO, maintains a wastewater treatment facility that processes 2.5 MGD on average and a maximum capacity of 6 MGD.

In 2012, the wastewater treatment plant installed the Duperon® FlexRake® Full Penetration Fine Screen (FPFS) to remove debris from the treatment stream. At the time, the drive head used with this screen used metal bearings that required maintenance in the form of regular greasing.

Ten years later, the FlexRake FPFS was still performing its job, but the facility was seeking options to eliminate bearing wear and the need for greasing. Just in time, the wastewater treatment facility has benefited from the rollout of Duperon’s new stainless-steel, rust-resistant fabricated drive head using grease-less Thordon bearings.

Constructed of stainless steel, the new drive head is corrosion- and rust-resistant, stands up to abrasion and offers superior longevity.

Thordon’s polymer bearings have an extended wear life due to their low operating friction and resistance to corrosion, impact and abrasion. They operate without greasing and therefore offer reduced maintenance demands and increased uptime. Without oil or grease discharge, Duperon’s new drive head offers an environmental improvement and compliance benefit. Additionally, end-users save money as they no longer have to purchase, store or dispose of oil, grease or environmentally acceptable lubricants (EAL) for use in the drive head.

For the St. Joseph Industrial Sewer District, the drive head replacement was a snap. The installation was smooth, and the FlexRake FPFS returned to service quickly and efficiently, doing its job of optimizing downstream process and equipment performance. Going forward, the St. Joseph industrial wastewater treatment facility will benefit from decreased operating costs in the form of less scheduled maintenance and time savings from not having to inspect the bearings as often. Duperon plans to inspect the site every two years as a preventive maintenance measure.

“We are always seeking solutions that are cost efficient without sacrificing quality,” said Chad Coleman, general manager, South St. Joseph Industrial Sewer District. “The new drive head offered by Duperon accomplishes that goal while also keeping the environment top of mind, another top priority at South St. Joseph Industrial Sewer District. Our team is grateful for the partnership with Duperon Corporation and looks forward to future improvements that will allow us to continue serving our community to the best of our ability.”

Duperon’s new fabricated drive head has made an already easy-to-maintain system even easier, further saving time and costs for this wastewater treatment facility.

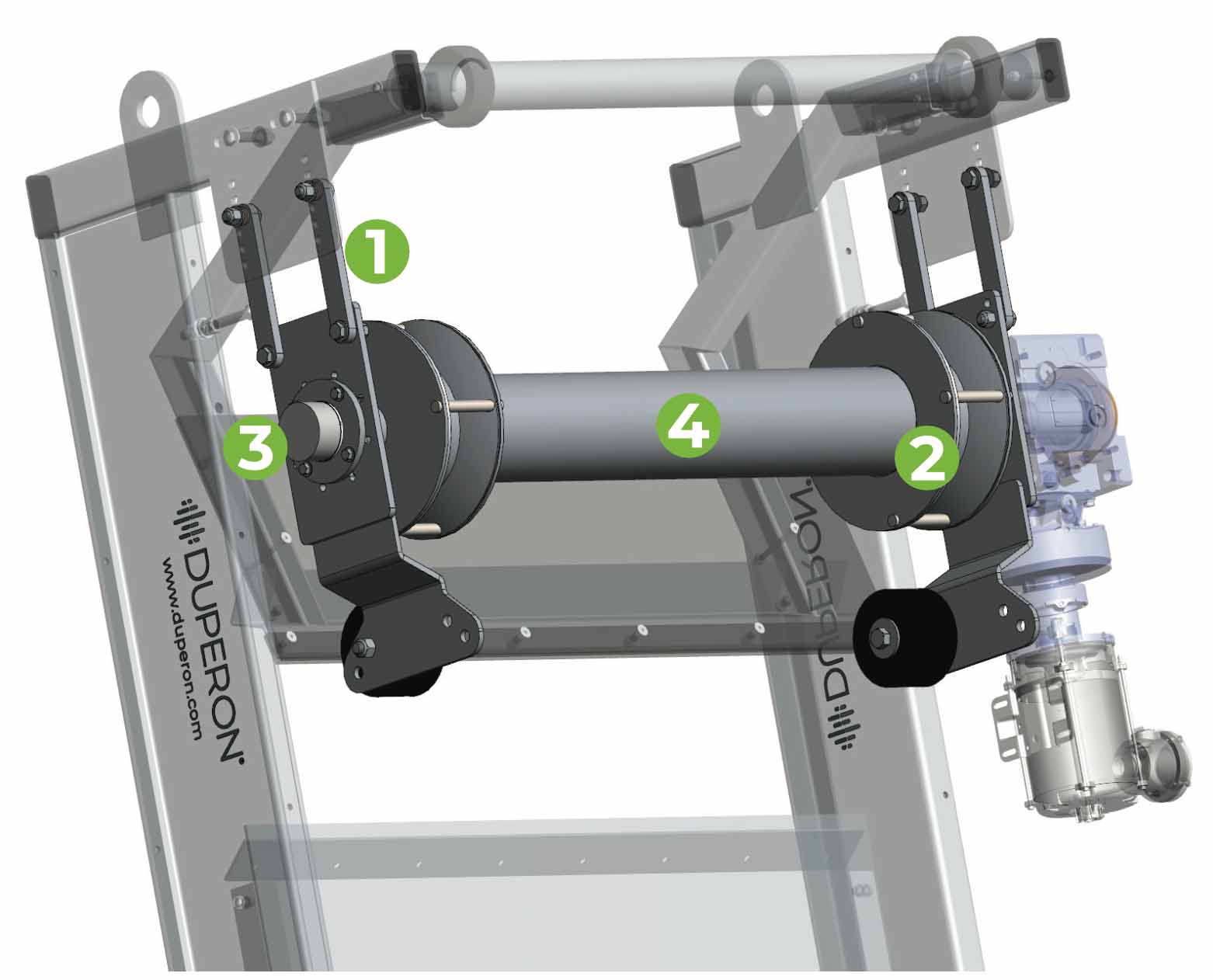

- EASE OF INSTALLATION

Ships and installs from the hinge bars. Standard as complete assembly with motor and gearbox installed. - DESIGNED FOR DUTY

Engineered with 2205 duplex stainless drive pins, which is more than twice the strength of 304SS or 316SS - LOW MAINTENANCE

Made with a Thordon Bearing on the end of the shaft so no greasing is required - BUILT TO LAST

Made of 304 or 316 stainless steel to avoid rusting and increase the lifespan of the drive head, as well as, no longer requires painting.