Conveyance

Debris Management Technologies

A full range of conveyance methods for process integrity

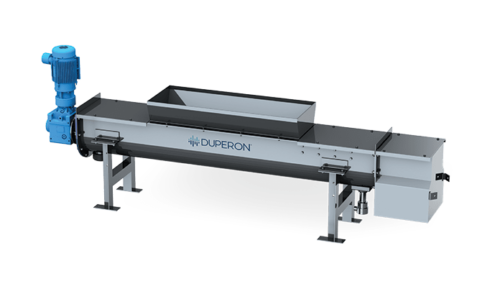

Fully Enclosed Conveyor Easily Transfers Debris, Keeps Materials and Odors Contained

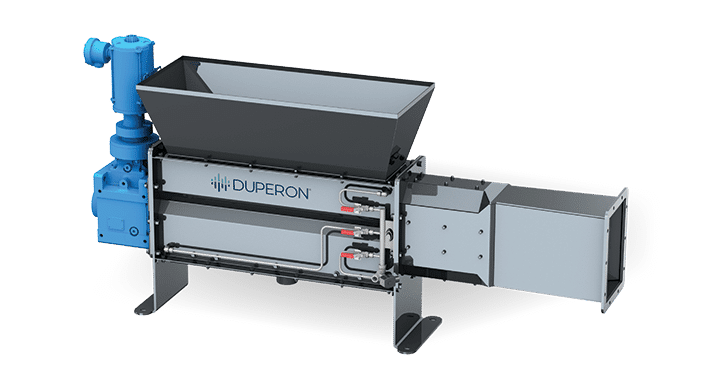

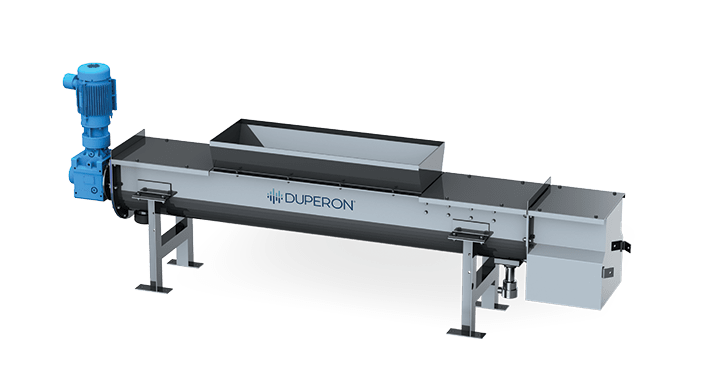

The Duperon® Shaftless Screw Conveyor is ideal for debris in wastewater and industrial applications. It is constructed of corrosion-resistant, stainless steel materials and meets CEMA 300 standards with safety features to protect personnel.

The Duperon Shaftless Screw Conveyor is compact, simple, and effectively transports materials from the screen or washer compactor to a desired discharge point. It is cost effective due to its low energy consumption and minimal maintenance.

Applications:

- Municipal Wastewater

- Industrial Applications

- And other wetted solids transport applications

The Duperon®

Difference

The Duperon®

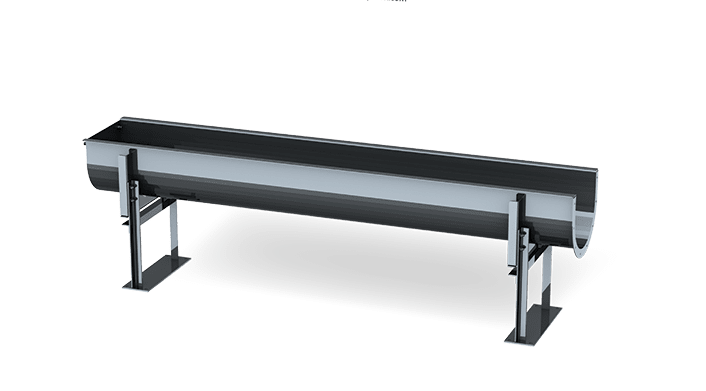

Shaftless Screw Conveyor

Simple and efficient design

Shaftless to optimize fill volume and no additional internal components

Automated

Transfers screenings to remote dumpster locations without manual labor required

Customizable

Unit length, number of inlet hoppers, and discharge options are designed to site needs

Process integrity

Integrates with FlexRake® discharge and synchronized response to rake speed and discharge rate

Clean operations

Odors from screened materials are fully contained

Long product life

All stainless steel or corrosion-resistant materials used

Description

The Shaftless Screw Conveyor uses a single shaftless screw to provide positive movement forward and optimized fill volume. It is housed in a covered stainless steel trough with UHMW pre-formed liners to minimize wear. A drain connection is provided to return liquids into the channel. Unit length, number of inlet hoppers, and discharge options are designed to the site.

General Specs

| Applications | Municipal wastewater

Industrial applications And other wetted solids transport applications |

| Conveyor Width | 20 in |

| Maximum Conveyor Length | 32 ft |

| Auger Diameter | 11.5 in |

| Orientation | Horizontal with incline option |

| Maximum Discharge Inclination | 25 degrees from horizontal |

| Maximum Capacity | Up to 50 cu.ft/hr |

| Typical Motor | 1 hp – 3 hp, site dependent |

| Materials of Construction | SSTL, UHMW-PE and 8620 coated alloy augers |

| Controls | Loss of rotation sensor

Optional VFD for variable speed |

| Safety | Emergency pull cord |

Key Features

Low maintenance and long product life

Low energy consumption with use of 1 hp – 3 hp depending on site needs/unit length

Shaftless spiral used to optimize fill volume

Enclosed U-Shaped trough with easily replaceable UHMW liner

Safety pull cord

Unit length, number of inlet hoppers, and discharge options are designed to the site needs.

Schematic

Photo Gallery

Related Products

Heat Trace and Blanket Kit: can be thermally protected from cold temperatures with the addition of the Heat Blanket with integral heat trace. Note this is required in applications where freezing temperatures are possible.

Drop Sleeve: A flexible, heavy-duty urethane canvas sleeve can be connected to the end of the Shaftless Screw Conveyor steel chute. The sleeve shall provide a guidance for dropping screenings to help contain the debris as it falls and prevent debris from being scattered.

Hinged covers: Covers can be provided with a hinge on one side and a quick connect clamp fitting on the other. :

Duperon has sluicing down to an art

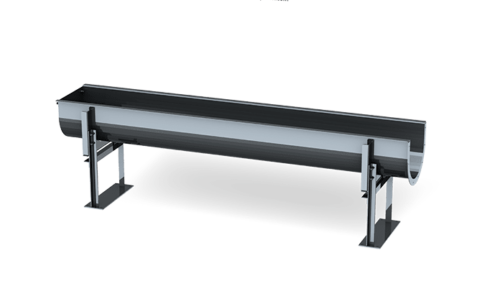

The Duperon sluice is a simple conveyance method using a stainless steel trough and flowing water to transfer discharged screenings. In municipal applications, sluices typically discharge into washer compactors for dewatering. In other applications such as flood control or raw water intakes, it may discharge downstream of the site or be transported to a bank or holding area.

This system of transport is often ideal when discharging from multiple screens, the site has long runs to move the debris to the final discharge point. A sluice may be cost effective by eliminating belts, multiple drives and other mechanical devices.

Our solutions are simple

There are basic factors that attribute to a successful sluice operation: debris volume management, water conversion (minimizing water usage while maintaining functionality) and velocity.

Duperon has implemented many sluices over the years and has mastered the distinctions across many industries and applications to assure that this option is successfully applied and engineered to your site.

Applications:

- Municipal Wastewater

- Industrial Applications

- Stormwater and Flood Control

- Open Channel Intakes

- And other wetted solids transport applications

The Duperon®

Difference

The Duperon®

Sluice

Process integrity

The successful transition of captured screenings to a Dual Auger Washer Compactor or other point of discharge assures system reliability

Configuration flexibility

Sluicing can be ideal for retrofits that have site constraints to transport debris to the desired discharge location

Customized solution

Pump sizing and volume, length, cornering angles, inlet feeds, and trough capacity customized to site needs

Cost-effective

A sluice offers an affordable conveyance method for long spans especially if an ample supply of water exists at the site

Simplicity

Eliminates belts, rollers, augers and other mechanical devices that require calibration, maintenance or replacement

Tell us about your project

‘You’ll like working with us’ is a commitment and the way we deliver extraordinary customer care for the full life-cycle of your equipment. This is how we strive to earn the privilege to serve your screening needs.

Description

A Duperon Sluice is a conveyance device that is ideal for long spans where the costs of multiple belt conveyors, or mechanical devices like augers, becomes prohibitive. Also sites realize additional economic benefit if they require turns or accommodations for existing structures, especially if they have an ample water supply.

The Sluice is constructed of non-corrosive materials such as stainless steel in the form of a trough. A pump will be sized as appropriate for the water volume required, as well as considerations for the number of screens discharging, the type and volume of debris.

It is often discharging into a washer compactor for dewatering (for municipal wastewater or industrial applications) or into other desired locations for raw water intakes or stormwater, flood control applications.

General Specs

| Applications | Municipal Wastewater

Open Channel Intakes Industrial Applications Stormwater and Flood Control |

| Sizing | Length and width customized to site |

| Capacity | Customized to site |

| Water Source | Potable or plant effluent |

| Water Volume | 40 GPM – 60 GPM |

| Water Pressure | Typically 50 PSI |

Key Features

Corrosion resistant materials

Minimal maintenance and long product life

Ability to be configured to the site

Simplicity in design: basically a pump and trough

Cost effective for long spans

Ability to manage the discharges of multiple screens

Schematic

Photo Gallery

Related Products

Design Collaboration

To build your solution, our engineers take the time to understand your facility, process, and goals.

We’ll combine our team’s experience with water screening, cleaning, and processing with your team’s detailed understanding of your product and process, so we can develop a reliable and cost-effective solution.