Dual Auger System

A solution to “flushable” wipes

An alternative to grinders and chopper pumps in the collection system and plant headworks

Wipes wreak havoc

in collection systems and downstream treatment when not removed… Imagine removing wipes before a small problem becomes a big problem.

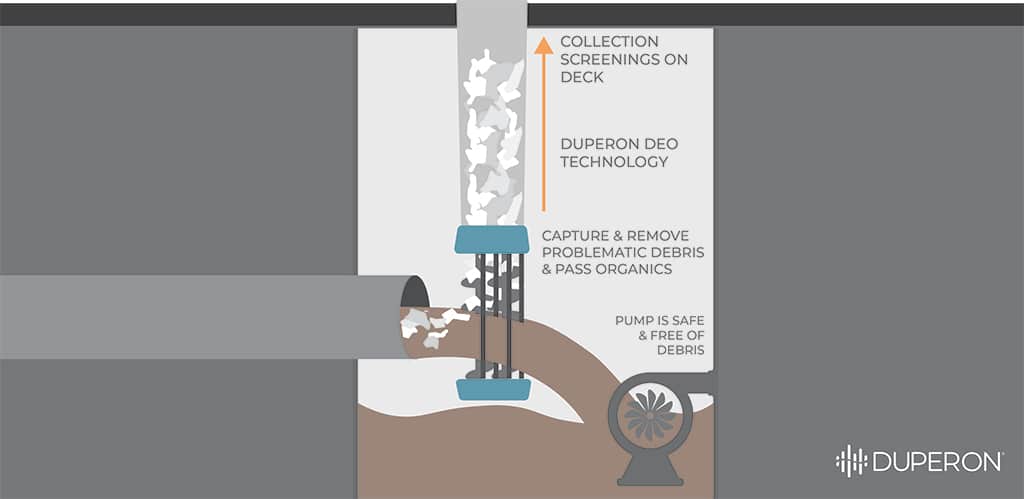

Operators no longer have to compromise between manually cleaning clogged pumps or using maintenance-intensive grinders that send debris downstream only to re-weave and become problematic again. Our design uses three proven Duperon technologies to capture and remove rags and other pump-fouling debris while keeping organics in the collection system.

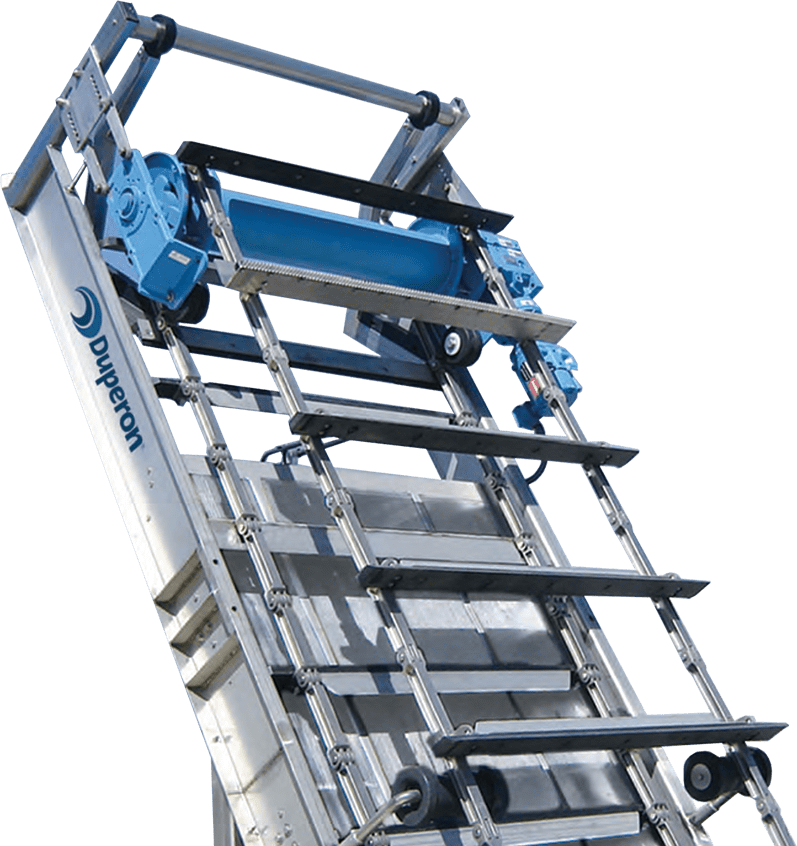

Introducing the Duperon Dual Auger System

a simple and compact screen that removes the majority of wipes and rags in the collection system. By removing non-dissolvable solids at (or near) the point they enter the collection system, the Dual Auger System restores systemwide integrity by allowing them to operate as they were designed, unimpeded by wipes.

… all with the simplicity and reliability that you have come to expect from Duperon innovation.

Applications:

- Wetwells

- Manholes

- Nursing homes

- Hospitals

- Campgrounds

- Truck stops

- Industrial applications

- Municipal headworks

- Package plants

The Duperon®

Difference

The Duperon®

Dual Auger System

Drastically reduces clogged pumps

Simple 5 in 1 System

Capture, dewater, compact, store and convey screenings all with one piece of equipment

Addresses the problem at its source

Deploy at high-ragging sites experiencing pump clogging to remove problematic debris before downstream equipment can be impacted

Compact footprint

Can be installed in manhole & wetwell applications as small as 17 inches

Eliminates emergency maintenance

Replaces it with planned (scheduled) and infrequent pickups

Description

The Dual Auger System is positioned in a wet well or manhole to catch the falling waste stream from the inlet pipe. The screening unit is comprised of two vertical counter-rotating augers driven by an electric motor. The motor is completely sealed in the upper housing. The Dual Auger System is fully submersible.

There is an overflow bypass opening ahead of the screening unit. The vertical bar screen has a .71 inch bar opening with other size options available. As screenings are captured, a discharge chute extends vertically to compact, dewater, lift, and store debris, without additional augers required. The solids are held in the chute or discharged into a bin, fully contained for odor control and aesthetics. Debris management is simple, with planned and infrequent pickups to dispose of solids.

General Specs

| Typical Applications |

|

| Application Size Information | Designed to fit into manholes as small as 17 inches

Max influent pipe size: 16 inches In-channel application available |

| Capacity | 1.0MGD (695 gpm) continuous flow (0.34″ opening)

1.5 MGD (1,042 gpm) continuous flow (0.71 opening) Flow exceeding max flow will begin to bypass |

| Main Unit Dimensions | 16 inches wide x 17 inches deep x 37 inches tall |

| Discharge Extension Chute | Captures, dewaters, compacts, conveys and stores screenings up to 40 feet vertically |

| Discharge Options | Below Deck Storage – Chute stops below deck. Chute is emptied by opening hatch/lift manhole cover and insert vacuum truck nozzle into discharge chute to remove debris.

On Deck Discharge – Chute extends above deck. Discharges horizontally into an adjacent bin. Bagger and freeze protection options are available. |

| Bar Screen | 0.34 inch or 0.71 inch opening

0.38 inch X 1.00 inch bar |

| Material of Construction | 304 SSTL & Painted Class 35 Grey Iron |

| Typical Motor | ½ hp 230/460 VAC/3ph explosion proof, non-ventilated. Unit is fully submersible |

| Standard Controls | Stand alone weatherproof VFD, padlock security and speed control. Custom panel options are available. |

| Installation | Install inlet pipe adapter with four (4) ½ inch concrete anchors. Use a small crane or portable gantry to lower unit down. Align trough to pipe adapter. Support discharge chute at deck level with four (4) ½ inch concrete anchors. No guides or rails required. |

Key Features

The Dual Auger System builds on three proven Duperon technologies:

- Positive displacement dual augers continuously clean the inlet by capturing and lifting solids

- Brushless self-cleaning eliminates maintenance

- Discharge extension chute conveys compacted debris without full length augers.

Built-in Bypass eliminates sewer backups during power outages

How it works – Video

Theory of design

Schematic

Photo Gallery

Case Studies

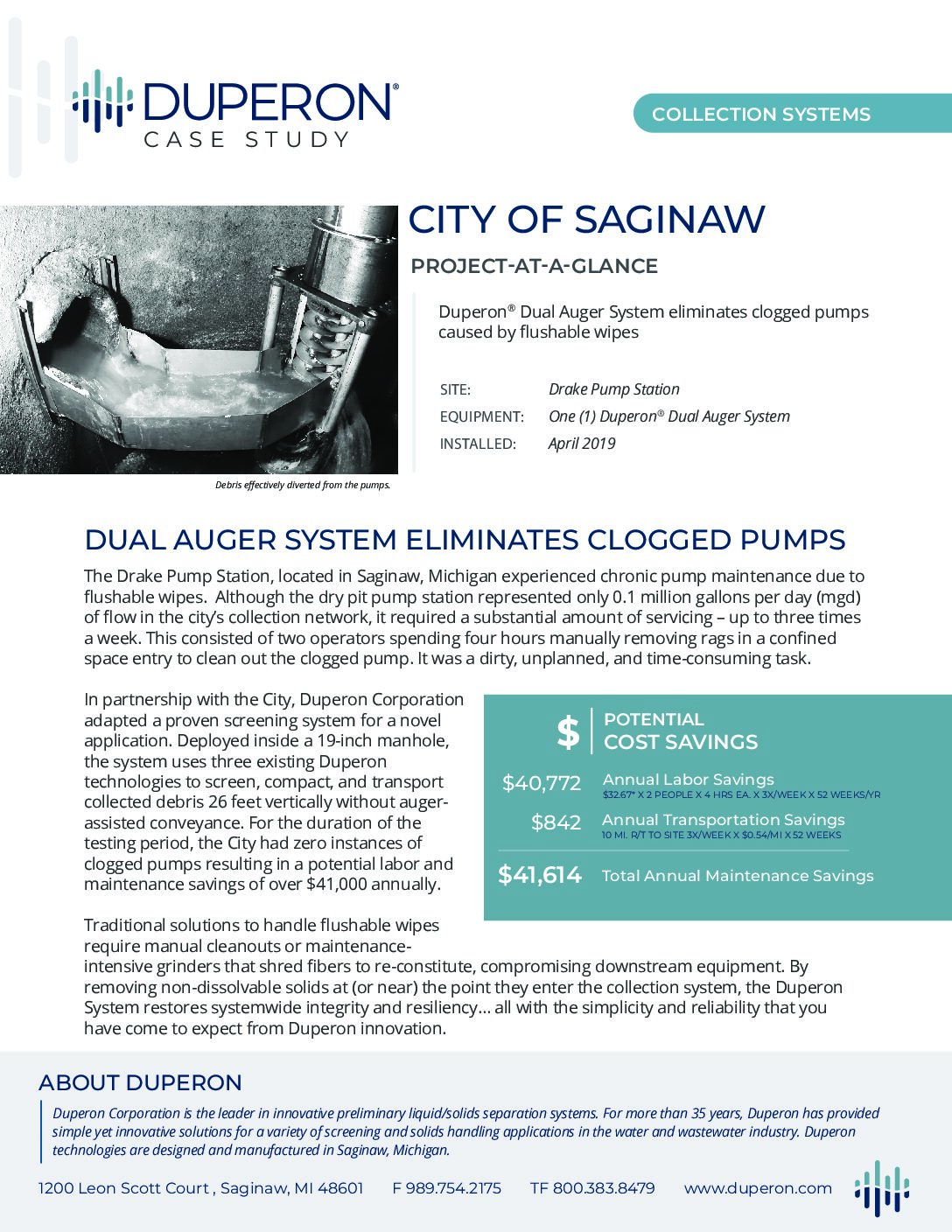

City of Saginaw Case Study

Duperon Dual Auger System eliminates clogged pumps caused by flushable wipes

Related Products

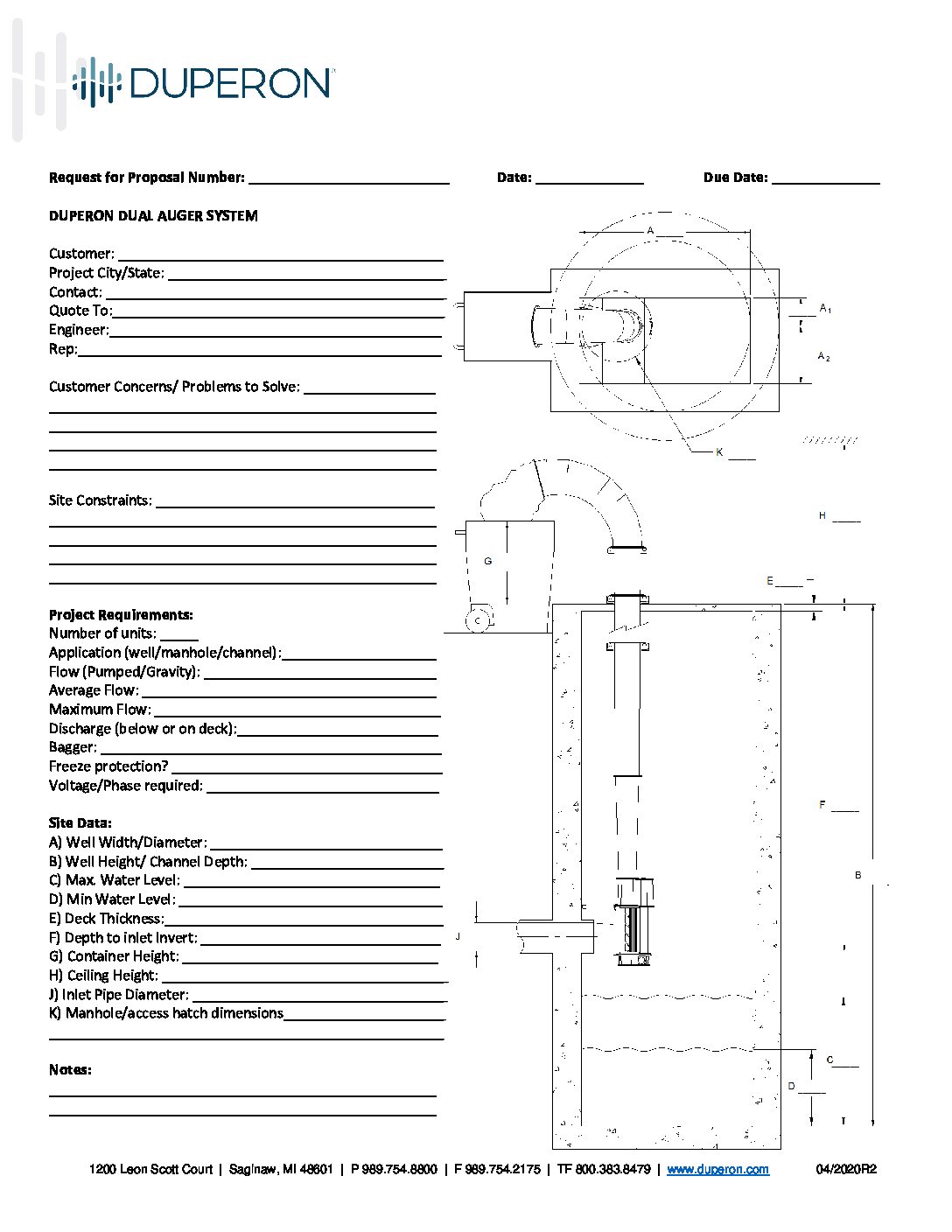

RFQ form

Tell us about your project

‘You’ll like working with us’ is a commitment and the way we deliver extraordinary customer care for the full life-cycle of your equipment. This is how we strive to earn the privilege to serve your continued screening needs.

Design Collaboration

To build your solution, our engineers take the time to understand your facility, process, and goals.

We’ll combine our team’s experience with water screening, cleaning, and processing with your team’s detailed understanding of your product and process, so we can develop a reliable and cost-effective solution.