Collection Systems

& Pump Stations

Fine and coarse screening solutions for pump protection

Screening made simple for collection systems

Collection systems are vital networks that convey suspended solids and dissolved materials found in wastewater to treatment plants. To operate effectively, it is critical they remain free of blockages that disrupt flow and surcharge sewers. Duperon has a variety of screening solutions to alleviate some of the challenges a sewer system faces today:

- ‘Flushable’ wipes Contrary to their name, ‘flushable’ wipes do not degrade in the collection system like traditional toilet paper. While they have been causing issues in the wastewater industry for quite some time, their growing popularity and the global covid pandemic have exacerbated the issue to a $1 billion dollar global problem. Until consumer behavior changes, (wipes in the trash versus down the toilet) screening systems will be required to effectively remove wipes to reduce the pump-clogging caused by them.

- Fats, Oils, Grease (FOG) refers to the improper disposal of residential and commercial byproducts from food preparation and cleaning that solidify into grease balls that clog sewer pipes. This is another main cause for sanitary sewer overflows. Hydro jetting and chemical dosing helps disperse FOG but can cause problems with downstream pumps and lift stations if equipment isn’t designed to handle this type of debris.

- Fatbergs go together with FOG and are fiber-enforced grease balls that clog sewer pipes. Flushable wipes are a contributor to this mass, along with household grease and other typical waste stream debris that congeal together and create blockages. Proper disposal of residential grease and wet wipes would help alleviate fatbergs but screening can also aid in removing harmful debris before it builds up.

- Inflow & Infiltration (I&I) is when surface water and groundwater enter into the sewer during seasonal or wet weather events as a result of aged infrastructure or improper connections. These excessive flows can overburden the collection system resulting in overflows, create large peaking factors in flow rate, and introduce sand, grit and other pollutants into the sewer. The additional water must be fully treated which creates costly treatment and higher capital expenditure at the wastewater plant. Screens that are adaptive to hydraulic and debris loading events are favorable in these conditions.

Collection systems are complex networks but Duperon’s approach is simple. Building resiliency in the collection system starts with necessary levels of screening to remove problematic debris before downstream pipes and equipment can be impacted. Pump stations typically deploy coarser openings to protect pumps while ensuring organics travel to the plant. Keeping the organics in and taking troublesome debris out restores systemwide resiliency by allowing the sewer system to operate as it was originally designed. Our team will work with you to provide customized solutions that are automated, low maintenance, and reduce clogged pumps and blocked pipes.

Applications

Duperon proven screening technologies can provide protection that reduce the risk of blocked pipes and clogging pumps in the following applications:

- Pump stations

- Lift stations

- Manholes

- Lateral sewers

- Branch sewers

- Main sewers

- Trunk sewers

- Interceptor sewers

- Gravity-fed sewers

- Pumped sewer systems

Solutions to address the following

Duperon partners with you to solve your unique collection system challenges and provides expertise in the following areas:

- Fine screens

- Coarse screens

- Mechanical bar screens

- Flushable wipes removal

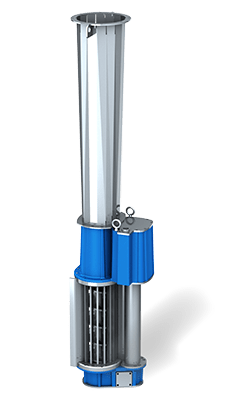

- Septage receiving

- Pump protection

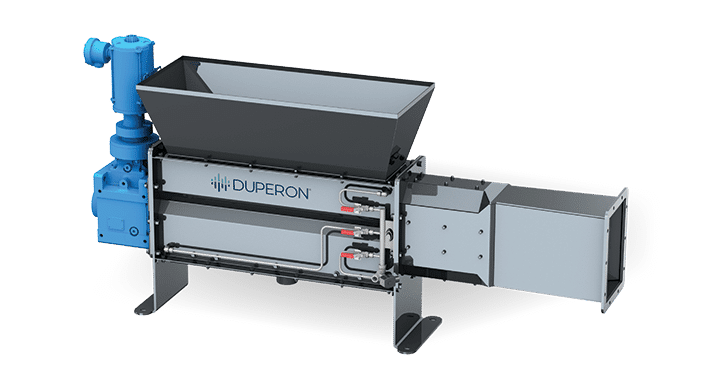

- Washing compacting

- Debris handling

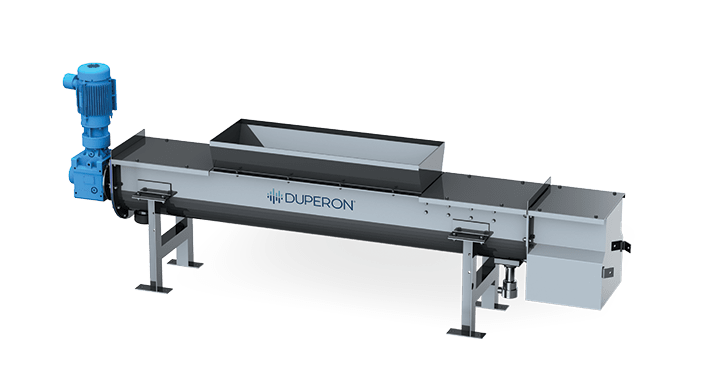

- Conveyance

The Duperon®

Difference

Return on investment

Few parts, minimal maintenance, and decreased costs associated with clogged pumps calculates into a quick payback period

Hands-off operation

Duperon equipment is easy to install, own and operate allowing your team and resources to focus on other treatment demands

Adaptive debris handling

Duperon technologies handles grease, grit, first flushes, rags, large or unusual debris (such as 2x4s or bricks) without shutdown or operator intervention

Process resilience

Effective solids removal through a broad range of flow and debris conditions so downstream assets remain protected

Customized solutions

Collection systems are not one size fits all and neither are Duperon’s solutions. We offer tailored designs to solve the unique challenges of your system

Partnership

‘You’ll like working with us’ is a commitment and way we deliver extraordinary customer care for the full life-cycle of your equipment. This is how we strive to earn the privilege to serve your continued screening needs

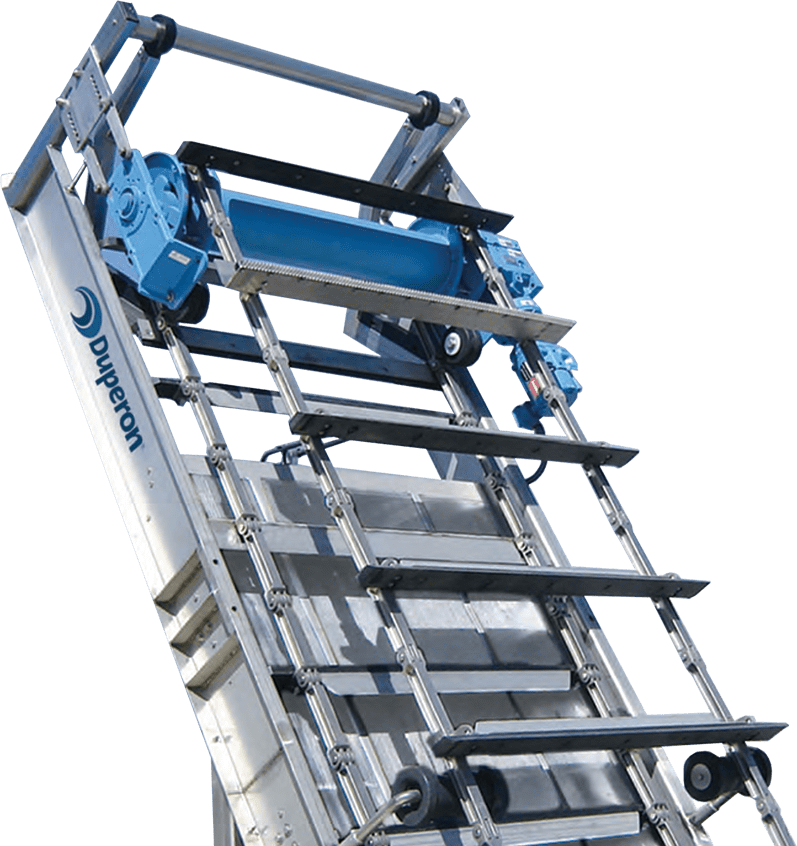

Coarse Screening

Bar openings greater than ½ in

Collection system and pump protection

Fine Screening

Openings ½ in down to 0.020 in

Solids removal typically at larger lift and pump stations

Debris Management

Collection and Conveyance

Processing and transport of collected screenings

You’ll like

working with us

Grease attack? No problem for the FlexRake®!

Randy Sommers

Superintendent, City of Monroe, MI

(Retired)

Collection System Products

Keeping pump stations working properly means using screening and solids handling solutions that work reliably. The durability and resilience behind our designs prevents jams and clogs in any situation, keeping the pump station protected.

Products quick guide

| Product Name | Screen Type | Bar Opening | Bar Type | Engineering |

|---|---|---|---|---|

| Dual Auger System | Coarse | ~¾ in | Slotted Bar, SSTL & coated housing | Pre- Engineered |

| FlexRake® IQ™ | Coarse & Fine | ⅛ in to 4 in | Slotted Bar, SSTL | Site Specific |

| FlexRake® IQ2™ | Coarse & Fine | ¼ in – 4 in | Slotted Bar, SSTL | Site Specific |

| FlexRake® Full Penetration Fine Screen | Fine | ¼ in to ½ in | Slotted Bar, SSTL | Site Specific |

| FlexRake® Full Penetration | Coarse | Greater than ½ in | Slotted Bar, SSTL | Site Specific |

| FlexRake® Heavy Duty | Coarse | 2 in – 4 in | Slotted Bar, SSTL in wastewater | Site Specific |

Tell us about your project

Do you have a liquid/solids separation challenge in your collection system? We are here to help solve it.

Design Collaboration

To build your solution, our engineers take the time to understand your facility, process, and goals.

We’ll combine our team’s experience with water screening, cleaning, and processing with your team’s detailed understanding of your product and process, so we can develop a reliable and cost-effective solution.